Five essential things when investing a concrete block production factory

You are looking for the information about concrete block making machine. This article will provide 5 inportant and useful things before making the invest decision.

Table of Contents [Ẩn]

What is a concrete block production line?

Concrete bock production line is a system having from 6 to 33 equipment (depend on the level of automation). It is designed to make concrete block (or cement brick). The main materials are byproducts such as dust stone, thermal slag, etc and cement.

In worldwide, concrete block production line is aslo called as concrete block making machine, block making machine, concrete block machine, cement brick making machine, concrete block machinery.

Four techlonogies of concrete block making machine

1. Concrete block making machine with table vibration method

Characteristics: this method has a vertical vibration (the horizontal vibration has been distructed by synchronous mechanism), vibrarion force is putted under mold. Concrete block is formed into the mold by vibration force and hydraulic pressing mechanism upper the mold.

Concrete block making machine with table vibration method

Principle: Vibrating force is created from centifugal force when rotating 2 eccentric shafts. The rotary motion is supplied by two electric motors (or hydraulic motor) through synchronous speed box to eccentric shafts. Horrizontal force will be distructed complete by synchronous speed box, there is only the vertiacal force to the mould.

2. Concrete block making machine with mold vibration method or mutil-point vibration

Characteristics: the vibration force will be layed in the mold. Concrete block will be formed into the mold by the vibration force and hydraulic pressing mechanism upper the mold.

Concrete block making machine with mold vibration method

Principle: 2 eccentric shafts are mounted on the mold directly and these do not synchrous the speed. Therefore, it has vibration both horizontally and vertically. The rotary motion of two essentric shafts are supplied by two stepless control electric motors through invetor.

3. Concrete block making machine with static pressing method

Characteristics: This method uses the pressing force from hydraulic cylinder to form block.

Concrete block making machine with static pressing method

Principle: Static pressing method uses a hydraulic cynlinder (one way or two ways) to form block.

4. Manual concrete block making machine

Characteristics: This is a popular machine. Because of low investment, it is suitable to household investment scale. But the quality of block is very low.

Manual concrete block making machine

Principle: The machine is designed simply, using a cable to move, vibration mechanism is mounted to the mold directly.

Choose concrete block production line

Choosing concrete block production line is the most important thing. This is some information for your reference.

| Criteria | Europe, Japan, Korea... | China | Vietnam |

| Investment cost | From 650.000 to 1.900.000 USD | From 86.000 to 500.000 USD | From 86.000 to 500.000 USD |

| Delivery time | 90 to 120 days | 50 to 60 days | 35 to 60 days |

| Durability | More than 15 years | More than 7 years | More than 7 years |

| Spare part cost | Very expensive | Average price | Low price |

The condition to invest a concrete block factory

To establish a concrete block factory, besides choosing concrete block making machine, you have to prepare land, workforce and built workshop.

The next is the legal procedures such as investment projects, land lease procedures, environmental impact assessment, fire prevention, construction permits ...

Each country has a different policy; you should research carefully before making decision.

Manage and operate a concrete block factory

1. Choose the materials

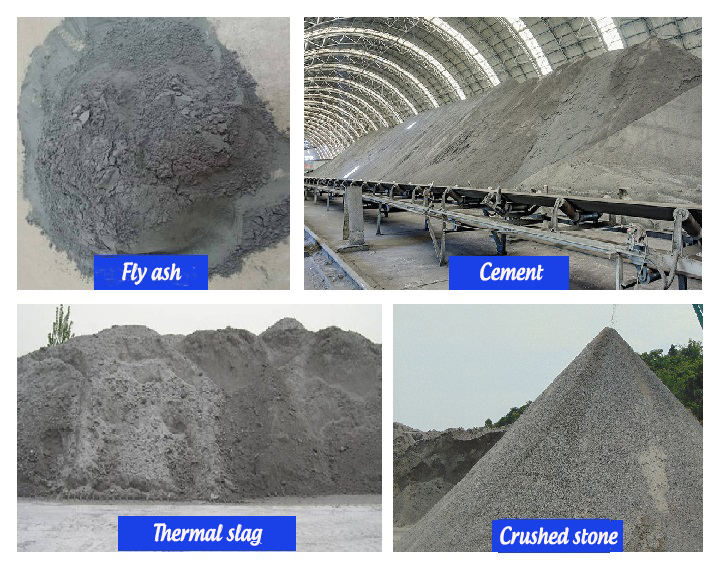

The main materials are dust stone, cement, fly ash and thermal slag. We should choose a clean type and PC40 to have a quality block.

The materials of concrete block

2. Manage the operation

Some investors do not pay attention to operation management. Therefore, the quality of block does not uniform. To overcome, you should:

- Adjust machine exactly

- Examine the scale carefully

- Check the mixing segment

- Adhere to block maintenance

With more than 14 experienced year, DMC commits to give the best products and services to customers, bring the maximum benefits to investors and achieve success together.