Maintain and repair the mechanical parts in a concrete block production line

During the operation of the concrete block making machine, you may face some troubles in mechanical system, which affects to your productivity. If you do not know the way to detect or overcome timely, it can lead to unexpected losses. DMC’s technician team will consult solutions to prevent and overcome.

Table of Contents [Ẩn]

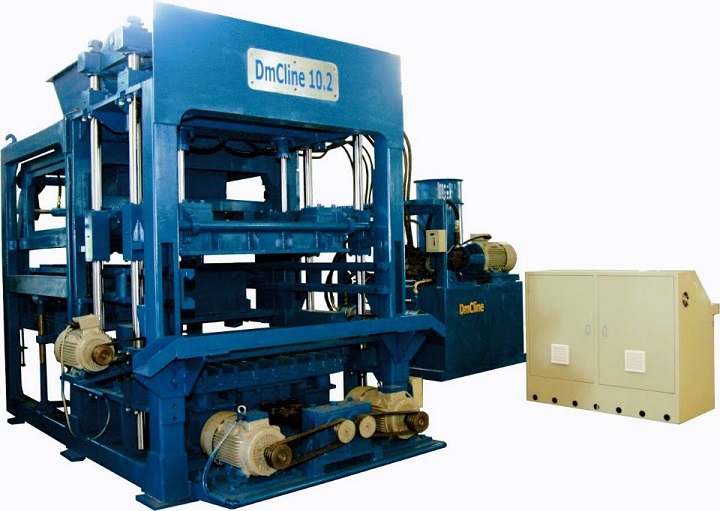

1. Maintain and repair concrete block making machine

The most important part in concrete block production line is pressing machine. It largely determines the quality of brick products as well as the productivity of the line. Therefore, you need to promptly detect the malfunction signs of the press machine and have solutions to overcome:

| Problems | Reasons | Solutions |

| The length of block is not uniformity | Check the abrasion of the part feeding material into mold | Build-up welding or replace this part |

| Lots of materials on the underbody | The pad and the ledges of the part feeding materials into mold are abraded | Examine and replace the ledges and pad if the abrasion level is too high |

| After forming, concrete block is broken, easy to crack, has low strength | The setting parameter is not exact | Adjust the parameters again; ensure to feed enough materials into mold uniformly. |

The part feeding materials into mold is abraded. So that, it cannot feed enough material into mold | Check and replace the part feeding material into mold when abraded | |

| Broke eccentric shaft and ball of vibrating box | Eccentric shaft has a low quality | Choose a reputation and experience supplier of concrete block making machine |

| The lubricating oil in the vibration box runs out leading to ball breakage and shaft breakage | Check the lubricating oil in the vibration box regularly for timely replenishment |

Maintain and repair the concrete block pressing machine

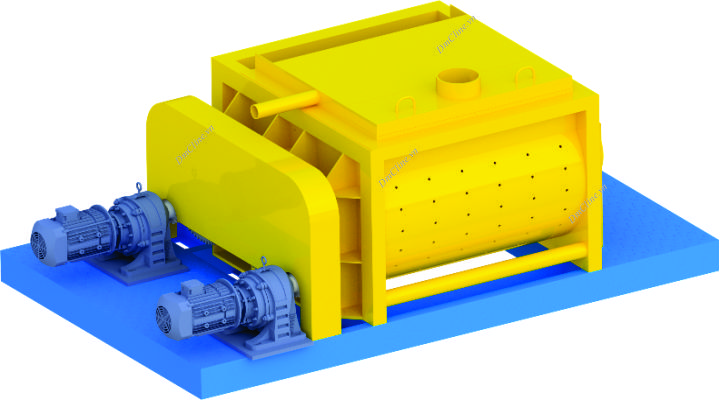

2. Maintain and repair the mixer

The material mixture, discharging from mixer, has a very low ratio of water (dry mixing). So that, the mixer is easy to damage. To enhance the durability of machine, you should:

| Problems | Reasons | Solutions |

Broke the mixing hand and mixing paddle | While cleaning the mixing tank because you used a concrete chisel machine | Only use pinch bar or chipping hammer to clean mixing tank |

| The mixer is overloaded and not working | You do not clean the mixing tank regularly or broke ball bearing | After a working shift, you need to clean mixing tank and spray fat into ball bearing and silver bearing |

| Mix material unevenly | Maybe the mixing hand or mixing paddle is abraded | Check and replace the abrasive mixing hands and mixing paddles |

| Strange noises are generated during operation | Stop machine and check ball bearing, speed synchronous box or bolt immediately | You need to overcome the broken part. |

| Besides, you need to pay attention to skip hoist position, detect the errors timely to avoid labor accident | Cable breakage, rail sag, wheel ball damage, winch bolt breakage. | You should check these position regularly to overcome timely |

Maintain and repair the mixer

3. Handle the adhesive phenomenon in cement silo

There are two main reasons:

+ The bottom of silo is designed non standardly

+ Silo stores much cement for a long time.

When this phenomenon happens, you should:

+ Using aeration: use an air compressor and spray air to the bottom of silo.

+ Using vibrator: mount the vibration motor onto the bottom of the silo, near the position of the screw conveyor (you should notice the position of the vibration motor, if you mount too high, the vibration force will be low. If you mount too low, it can only vibrate the discharge door of silo)...

Notes:

During operation, you may hear any strange sound in some parts such as batching machine, screw conveyor, belt conveyor, press machine, pallet feeder, block conveyor. These errors usually occur in bearing, vibrating box, bolt, cylinder, gear, etc. You should check to maintain and replace timely.

After a working shift, you need to comply with our guidance: Clean the materials sticking in the equipment, spray oil into motion area, fill oil into gearbox and reducer, etc.

>> See more "Concrete block and some common questions"

>> 5 essential things when investing a concrete block production factory

If you meet any trouble during operation, feel free contact DMC for consultation quickly. We are willing to support you.

Doan Minh Cong