Concrete block and some common questions?

1. What is unburnt brick?

Unburnt brick is a type of build brick, interlocking paver block, etc, which is formed and cured without burning by coal, electricity or other energy source.

Unbrick includes 3 groups:

- Group 1: Concrete block

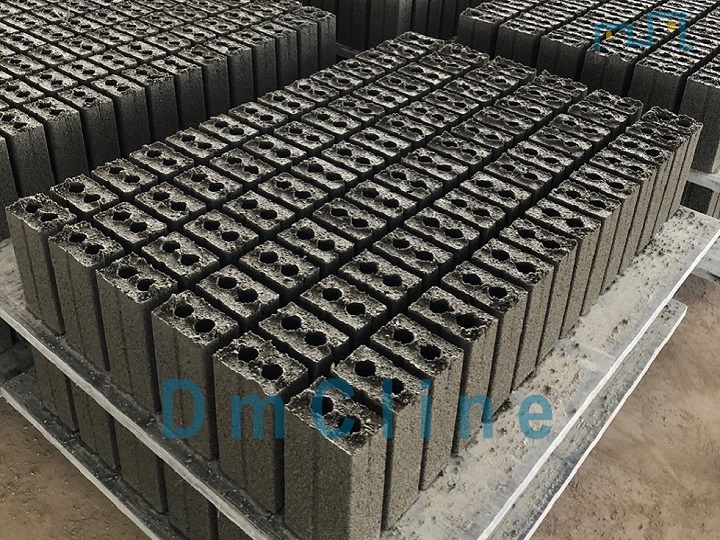

The main materials are cement, crushed stone and water, which are formed in the mold by hydraulic pressing and vibrating method. It needs to maintain as process to ensure the technical specifications and quality of block. Concrete blocks have a good adhesiveness, very few gaps so they do not absorb much water. The durability also enhances because of a large vibrating force (200kg/cm2). With a modern technology, the machine can produce many types of blocks such as solid block, hollow block, interlocking paver block, grass-paving block and meet the requirements of construction. So that, concrete block is one of the most used unburnt brick in construction, especially in the large projects and tall building projects, etc.

Concrete blocks are produced by DMCLINE concrete block production line

- Group 2: Lightweight concrete block

There are two types in this group, include AAC block and CLC block

CLC block | AAC block |

Advantages: lightweight (density is about 800-1200 kg/m3), thermal insulation. Disadvantages: the strength is not high, difficult to construction, using a special purpose motar. It is not suitable for the hot and humid climates and it is easy to crack wall and absorb water | |

Cellular Lightweight Concrete is a lightweight concrete type, having many tiny air holes. The main materials are cement, thermal fly ash, synthetic, foaming agent and some other additives | Use lime + cement + sand + aluminum powder and cured by autoclave.

|

- Group 3: Other types such as laterite brick, Split stone bricks

2. The water proof and crack of using unburnt brick

If the wall is permeated and cracked, it will be not only non-aesthetics but also unsafeness for users. In fact, there are some subjective and objective reasons. The phenomenon of cracking wall has many causes related to the structure of the building, only a few related to the choice of bricks and construction methods as some of the phenomena listed below:

2.1. The wall cracks vertically because of the high resilience of humidity and temperature

Tropical climate is one of the important reasons. If you use lightweight concrete block and do not use special purpose mortar or conform to construction process, it will be easy to crack and permeat. Lightweight concrete block has a low strength, a low resilience. Therefore, it is not suitable to tropical climate.

How to fix: use the special purpose mortar, choose an experienced construction contractor, construct as the process.

2.2. The wall does not crack but still water absorption

These are some reasons:

- The wall is built by unburnt brick with a high porosity.

- The wall is not mortared or the thickness of mortar layer is thin.

How to fix: Choose concrete block with a high water proof from the prestigious concrete block production factory with modern technology.

The wall does not crack but still water absorption

2.3. The wall is permeated and cracked due to the non-uniformity of vertical mortar circuit

This phenomenon usually occurs in some construction using concrete block with a large dimension and a large thickness. The main reason is the construction habits of workers. Commonly, concrete blocks have a small size and a small thickness (from 5 to 6 cm), the amount of mortar between the two masonry bricks is filled thickly tightly.

However, if you use concrete block having large size and thickness from 12 to 20 cm, the amount of mortar between the two masonry bricks is not filled thickly, tightly. So that, the mortar circuit will be open after drying.

To overcome, you need to fill mortar thickly and tightly into the mortar circuit.

3. Why can concrete blocks, which manufactured under waterproofing standards, replace clay bricks?

Concrete blocks are produced by modern technology. So that, it has a high strength and the water immnersion rate as the standard and a good waterproof. Especially, a modern concrete block production line can produce many types of block with the variety of models, the different strength and waterproof as the special standard of each project.

4. Can clay bricks and other types of brick replace concrete block?

Only concrete block, which is produced by a modern concrete block production line as DMCLINE, can meet the need of a high strength for projects.

The types of clay bricks and manual concrete block can not meet the need of contrustion.

5. Can manual concrete block replace clay brick?

Manual concrete block with the simple technology can only produce the low strength and a high water immersion rate. So that, it is only used in the small auxiliary projects

6. The mortar uses for concrete block?

Lightweight concrete block has to use a special purpose mortar. However, concrete block making machine is not the same to this. Concrete block only need the common mortar.

Concrete block is produced by a high technology, having a smooth surface. So that, it saves the amount of mortar.

7. Assemble the water and electric system on the construction using concrete block

It is more difficult to assemble the buried wire if using concrete block compare to clay brick.

However, it can be overcome by using cutter.

The thickness of block partition is 2-2.5 times as hollow clay brick. So that, you can drill or cut without worrying about broken

8. Why should we use concrete block instead of clay brick?

These are the advantages of using concrete block:

- First, in terms of civilization

Many countries in the world use concrete block such as USA, Japan, Germany, France, and ect. Concrete blocks catch up the development of construction in the world.

- Second, in terms of certainty and sustainability

Cocnrete blocks are made from concrete, which is produced by the modern technology. It has higher bearing strength than traditional clay brick. The strength of concrete block is more than 100 kg/cm2 with solid concrete block and more than 75 kg/cm2 with hollow concrete block. So that, the ratio of broken block is very low.

- Third, in terms of economy

The price of concrete block is cheaper than clay brick

Save mortar and construction time and the weight of wall is lighter because concrete block has a uniform size.

- Fourth, in term of utilities

Concrete block has many thick partition, it helps sound insulation, thermal insulation, water proof and safety.

Keangnam Tower in Vietnam

Doan Minh Cong