Part 3: Innovate batching system for concrete block production line – model 2020

This is the third article in series, which we introduce about the 4th version of DMCLINE - this version will be sold offically in the early of 2020.

Batching system is in charge of feeeding and mixing all materials together, then transfering materials after mixing to concrete block making machine. So, this system must operate steadily, mixing productivity must meet the capacity of block making machine, easy to clean and repair, ect.

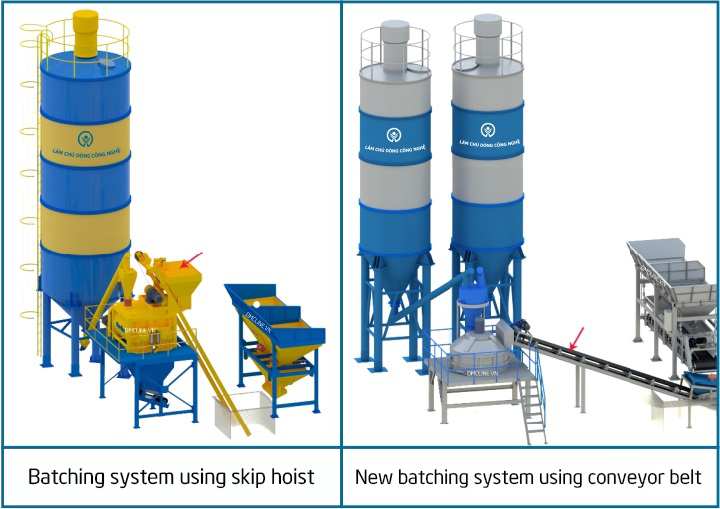

1. Remove skip hoist in batching system

If you have ever operated the mixer having skip hoist, surely you will have trouble with it many times. From the middle of 2019, DMCLINE concrete block production line has removed skip hoist completely, replaced by using conveyor belt.

This removal will no longer have problems related to skip hoist such as break of winch cable, bend of rail. Moreover, it helps to save cost of maintaince and repair, easy to clean mixing bucket and save areas for installing machine, ect.

Batching system in production of concrete block

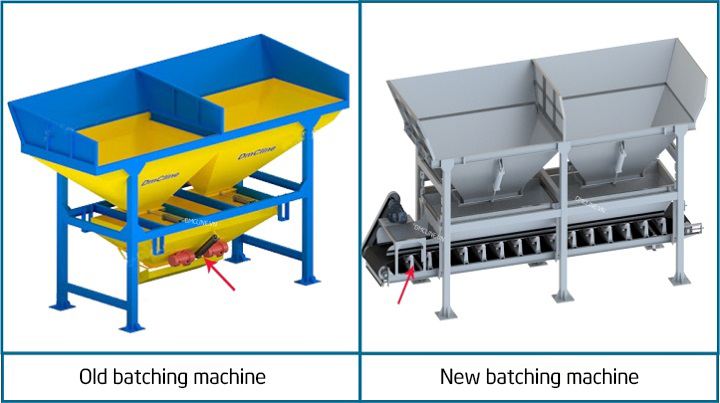

2. Apply PLC to batching machine

DMCLINE has applied PLC to material weighing process of concrete block making machine from the middle of 2019.

DMCLINE new batching machine uses the type of scale on conveyor belt and weighs materials by PLC S7-1200 control system. This has outstanding advantages about accuracy of weight, flexibility of discharge process, overcoming spillage of materials outside, ect.

Batching machine is also called as PL in concrete block production line

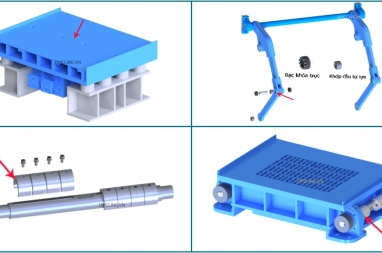

Special purpose JS mixer for production of concrete block

Nowadays, two shaft horizontal mixer is used popularly in the market to mix concrete. It is not manufactured to optimize for mixing aggregate in concrete block production.

We have researched, designed and processed successfully optimal mixing bucket to mixing aggregate for producing conrete block. Mixing bucket uses two engines mounted directly on reducer (cycloid type) to make pivoting motion for mixing shaft. It helps to distribute evenly load on two gears of two mixing shafts.The ball reducer type cycloid has oustanding advantages such as the overload bearing capacity, the abrasion resistance of ball discs.

Mixer in concrete block production line

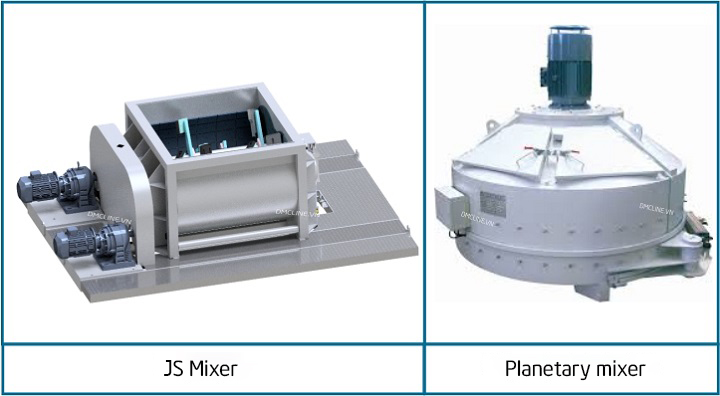

JS Mixer series, which is manufactured by DMC, has many advantages. But planetary mixer still has many outstanding advantages compared to JS mixer such as quick mixing time, regularity, less adhension, easy to clean mixing bucket, low motor power, high durablity of abrasion resistance parts such as hand pads, barrel pads, ect. However, planetary mixer has a high price. Which mixer to choose depends on your financial resources

For more consultance about batching system in production of concrete block, please contact us via Hotline: (+84) 975 08 6789.

>> Refer to more articles about new technology in the 4th version of DMCLINE concrete block production line:

- Part 1: Application of servo motor to concrete block production line – model 2020

- Part 2: Mechanical innovation in concrete block production line – model 2020

Doan Minh Cong