Part 2: 5 mechanical innovations in concrete block production line – model 2020

This efficient innovation is based on the sincere opinions from DMCLINE’s customers. DMC Group would like to thank for the highly valuable opinions.

This is the second article in series, which we introduce about the 4th version of DMCLINE – this version will be sold offically in the early of 2020.

Table of Contents [Ẩn]

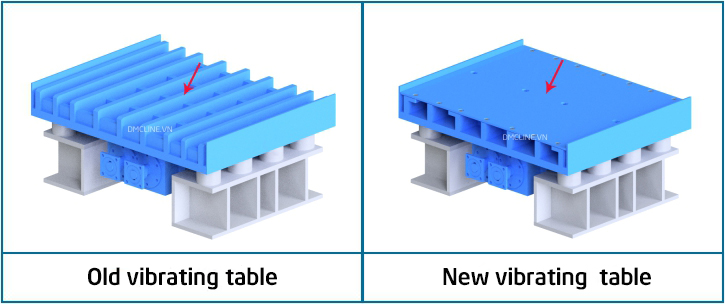

1. Innovate vibrating table for forming block

The noise and broken of plastic tray are the persistent problems of many concrete block production brand (include domestic and foreign brand). After monitoring as well as evaluating, we detect that the bearing bar of plastic tray is the cause of two above problems.

To overcome, we have fitted a bolster additionally using special purpose steel, which can withstand abrasion and strong vibration to increase the contact area between vibrating table and block tray. So it can overcome the crack of plastic tray in block pressing process, the noise when vibrating also reduce.

Innovate vibrating table of block making machine – version 2020

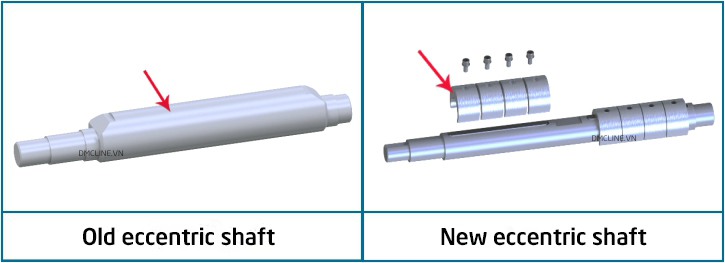

2. Modify eccentric shaft of vibrating box

The broken of eccentric shaft adds an extra cost and waiting time for processing. Set your mind at rest with 4th version of DMCLINE.

We have used prefabricated structure between concentric shaft and eccentric cam. This method help to adjust centifugal force of shaft easily by adding or reducing pieces of eccentric cam. The cost for replacing shaft is lower because we only need to replace concentric shaft and pieces of eccentric shaft can recycle.

Eccentric shaft of concrete block making machine – version 2020

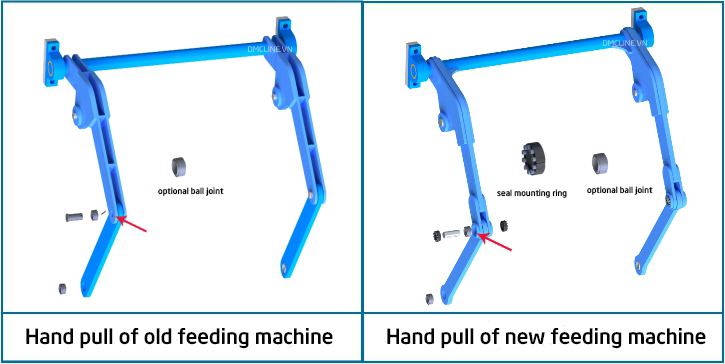

3. Innovate hand pull of feeding machine

If you have been using concrete block production line, surely your machine is had the abrasive hole in pivot position many time

We have compacted optional ball joint and seal mounting ring in pivot position. It helps to delete fully backlash when assembling, structure moves smoothly, overcome fully the abrasive hole in pivot position, easy to demount, assemble, maintain and replace.

Hand pull of feeding machine for block making machine- version 2020

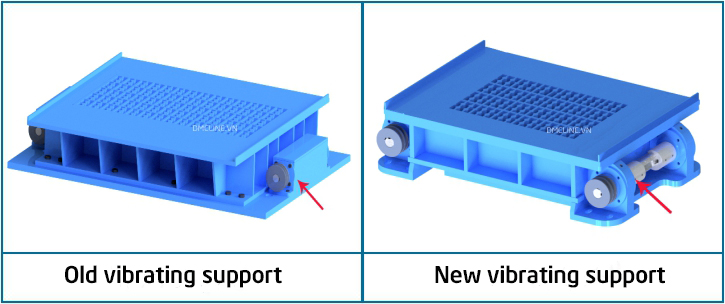

4. Modify vibrating support part

From 2015, vibrating mechanism is a wonderful solution to produce thin partition blocks, especially horizontal hollow block (tuynel hollow block). However, with the old design, it usually has problems such as breakage of ball or shaft.

In the late of 2018, we have designed new vibrating support, which has structure mounted directly with mould. Eccentric shaft is assembled from concentric shaft and pieces of eccentric cam. The advantages are firm structure, overcoming completely the broken of nut or shaft end compared to old design, allowing to adjust custom vibration force when changing the number of eccentric cams mounted on axis, easy to demount, assemble, maintain and replace.

Vibrating support is also called as auxiliary vibration of concrete block making machine

5. Innovate hydraulic system

The special thing of hydraulic systems is that it can operate in parallel (pressing and lifting mould at the same time). This is the best solution to produce blocks with high friction at partition. In addition, hydraulic system also innovates 3 points below:

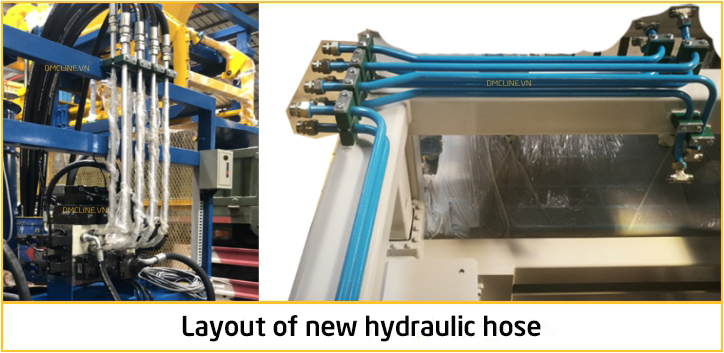

a. Hydraulic oil hose and spare part: Most of the hydraulic oil hose are replaced by rigid hose, bending combined with satellite main and spare part such as pipe clamps, junction, coupler, tee, ect. They are special purpose spare part according to DIN standards, ensuring aesthetics, easy to demount, assemble, maintain and replace.

Hydraulic system of concrete block production line

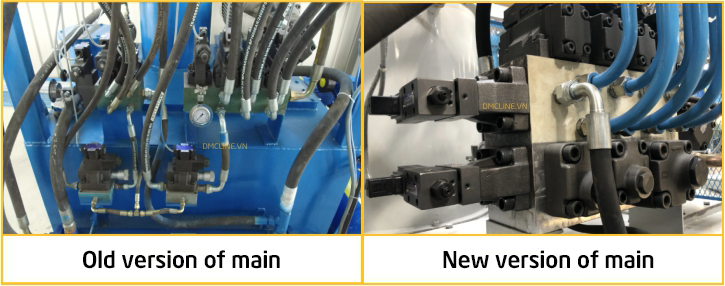

b. Hose for transferring oil in main: New hydraulic main system is designed with large oil transfering hose to discharge oil quickly, minimize friction and reduce heat of oil.

c. Dissolve oil flow: Main is designed in a seamless way so that the oil flow of the two pumps is neutralized, which helps the cylinder's travel move faster, shorten the pressing process.

Hydraulic main of concrete block making machine – model 2020

Hydraulic main of concrete block making machine – model 2020

We are sure that 5 above innovations will bring great benefits to investors. For the more details, please contact us via Hotline: (+84) 975 08 6789.

Doan Minh Cong