Fly ash bricks machine F9

Ý nghĩa tên gọi F9 The meaning of name F9

- F is the code of fly ash bricks machine with DMCLINE brand name;

- 9 is the quantity of bricks per pressing time with the dimension of 230x110x75mm.

Technical specification of fly ash bricks machine F9

Designed capacity | 9 pcs/pressing time equivalent to 17.280 pcs/8h |

Cycled time | 15-25s |

Pressing method | Static press |

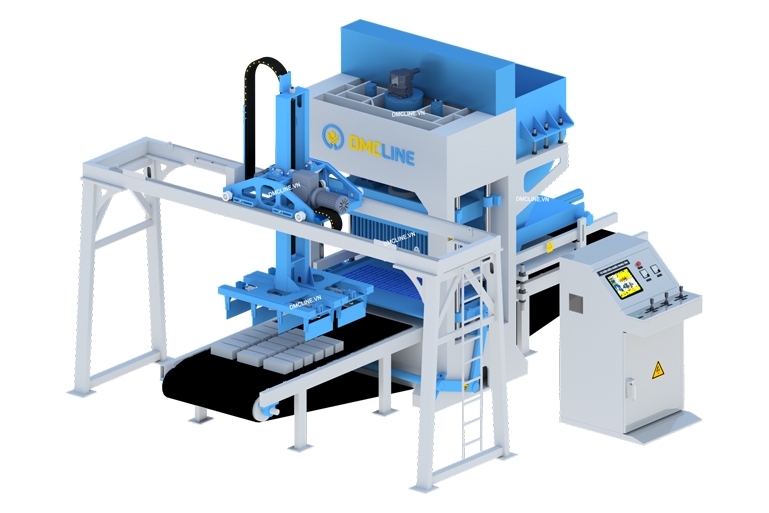

Dimension of machine | 5200x1750x2800mm |

Warranty | 12 months |

Place of origin | DMC, Vietnam |

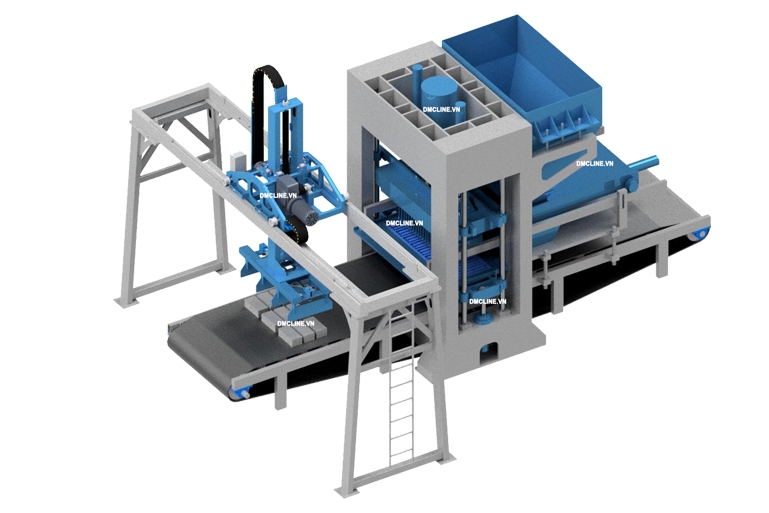

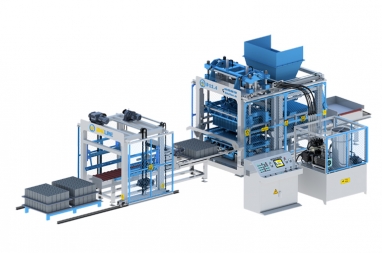

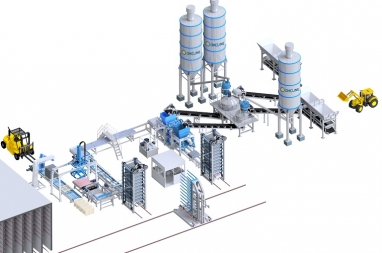

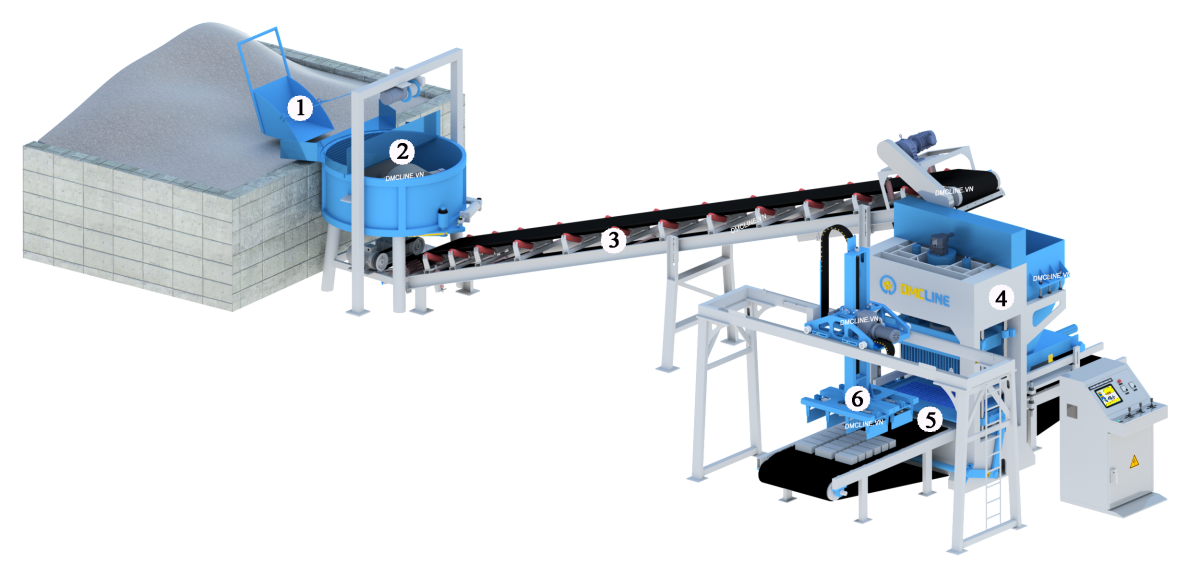

Technology description of fly ash bricks machine F9-G2

1. Hoist tipping bucket: Hoist the aggregates (grind stone, sand, thermol slag, ect) to pan mixer.

1. Hoist tipping bucket: Hoist the aggregates (grind stone, sand, thermol slag, ect) to pan mixer.

2. Pan mixer: Mix the materials (flyash, crusher dust, cement, water, ect) evenly. The materials mixture after mixing are discharged to belt conveyor.

3. Belt conveyor: Transfer the materials mixture after mixing from pan mixer to bricking making machine

4. Brick making machine: Create a large pressing force to form brick with high quality and stability.

5. Brick conveyor: Transfer brick after forming to the position of brick stacker

6. Brick stacker: Receive brick from brick conveyor and stack into bales

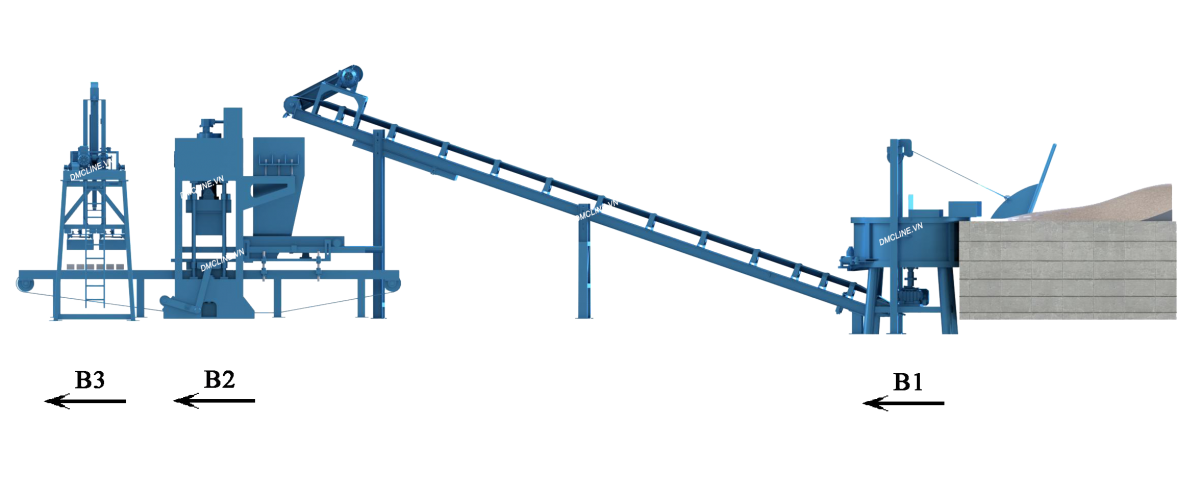

Production process of fly ash bricks machine F9-G2

Step 1: The workers feed stone, sand, cement, fly ash and water to pan mixer and mix the materials together.

Step 2: Brick making machine forms brick as the template. The workers must usually check to adjust machine to limit fault product.

Step 3: Brick stacker receives brick from brick conveyor, stack into each bale and workers trasfer to drying yard

Related products

Dây chuyền sản xuất khối bê tông DmCline D10 với công suất cao , “1 lần ép được 88 miếng khối rỗng, 1 giờ có thể ép được 7480 miếng khối rỗng”, tự động hóa từ cấp liệu đến xếp chồng , “sử dụng 07 công nhân vận hành”, máy tạo khối với tốc độ cao, bảo hành một (01) năm. Báo giá dây chuyền sản xuất Bê tông khối?

High quality concrete block production line with high pressure, 1 time can press 117 pieces of hollow block, 1 hour can press 9945 pieces of hollow block, Full automation, block making machine with high speed, “using 07 operation workers”, one (1) year warranty

Concrete block making machine, Concrete block casting machine, 42 million standard pieces per year warranty, combining 3 in 1 vibration and press, steadibility operation, “using 07 operation workers”, one (1) year warrantly.

Up to 2019, the D15.4 Concrete Block Making Machine is the largest machine in Vietnam with the capacity of “100 mililion standard pieces per year”, 100% automation, “using 7 operation workers”, one (1) year warranty. The line is created and developed by DmC Company. any.

semi-automatic concrete block making machine; the price of block making machine with the capacity of 24 million standard pieces per year, automatic bock making machine, What is the price of block making machine “using 03 operation workers”, one (1) year warranty.

Concrete block making/pressing machine with the capacity of 20 million standard pieces per year, semi-automatic concrete block making/pressing machine. The price of block making/pressing machine, using “03 operation workers”, one (1) year warranty. What is the price of block making/pressing machine?