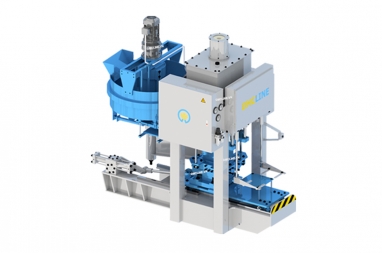

Cement tile making machine

DMCLINE is the brandname of non-fired building materials production line, which are manufactured and transferred by DMC.

Cement tile making machine DMCLINE is operated according to hydrauclic pressing principle (wet pressing technology), using hydraulic cynlinder to create a pressing force to form products

Producing color cement tiles by wet pressing technology has high productivity, stable quality of products, meet the standards and esthetics for construction

At the present, DMC has sold 2 models of cement tile making machine N8–140T and N8–200T to the market.

We are ready to:

- Consult fully about the investment procedures such as: Make the investment projects; Plan the factory; Organize the operating and manufacturing; Consult about ISO; Form the price list; Product conformity; etc.

- Supply cement tile production line with the capacity up to 000.000m2/year/line with a low initial cost investment, help customers approach the advanced production technology more easily.

- Service policy 24/24, minimize the disruption production due to the faults. Therefore, reducing many types of operating cost such as the cost for depreciation, finance and labor,…

DMC commits to give the best products and services to customers, bring the maximum benefits to investors and achieve the success together.

Cement tiles making machine with wet pressing technology, high quality. Maximum pressing force up to 240T, the capacity of 2 million m2/year. Quick tile making machine, leading reputable brand, Dedicated consultancy. Thoughtful warrranty

Cement tile making machine with high quality, leading prestigious brand. Maximum press force up to 160T, quick tile making machine “ producing 3840 pieces/shift”, “ using 04 operation workers”. 01 year warranty.

Cement tile mold with best price, high quality, high durability, leading reputation brand. Design the mould as customer’s requirements, produce within 15 days, thoughtful warranty