Research on cement tile mold

Mold is the most important part of non-fired building material making machinery as well as cement tile making machine. It has the direct impact to the precision and the quality of product.

Table of Contents [Ẩn]

What kinds of cement tile can the mold produce?

Cement tile mold is a metal mold, which is manufactured by special purposed steel and modern technology. Therefore, it has a high quality, meet the requirements of the malleable inner layer and the hard outer layer to work constantly in the high strength environment without abrasion.

Cement tile mold is an important part, mounted on tile pressing machine to form cement tile and affect to the quality as well as the aesthetic of cement tile.

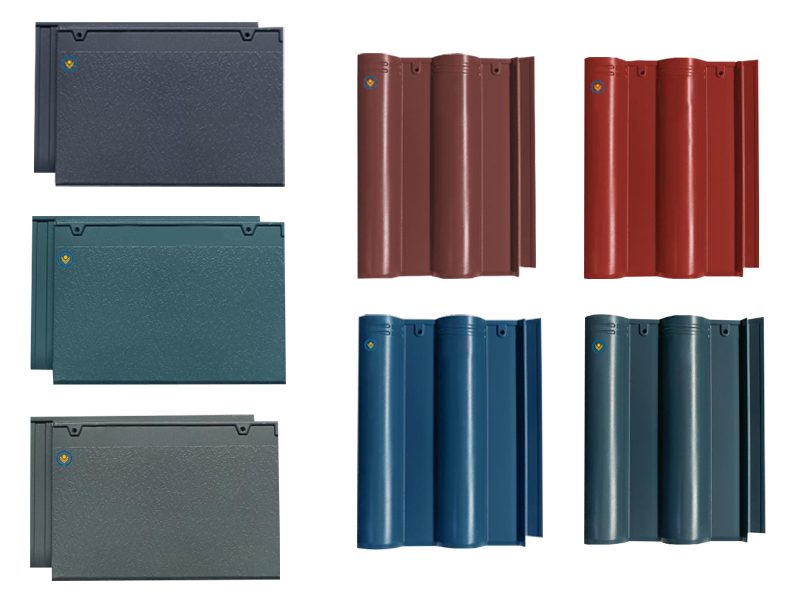

Depend on the size of tile, there are from 9 to 11 pcs per meter. Based on the design or drawing, there are 2 types: flat tile and corrugated tile.

In which, flat tile and accessories has a higher price and a few customers choose it. Because, it is usually used for villas, garden villas, private architecture.

Corrugated tile and accesories are usually used for main roof, gate roof, decorative roof, etc.

Some popular tiles in Vietnam

Some popular tiles in Vietnam

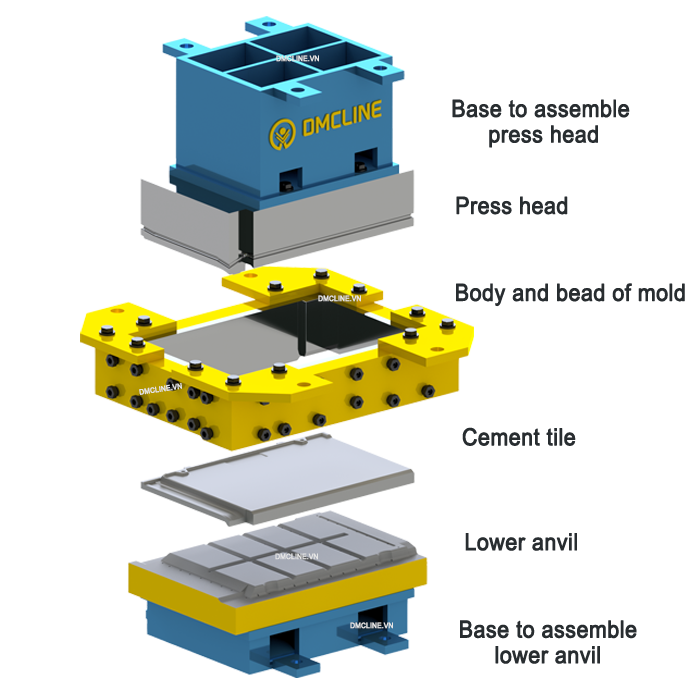

The structure of cement roof tile mold

Roof tile mold is made from special purpose steel and it is an important part in the pressing machine. It has many parts including: base to assemble pressing hard, press hard, body and bead of mold, lower anvil, base to assemble lower anvil.

In which, lower anvil, press head and bead of mold is the three most important parts, decide the shape and quality of tile.

+ Low anvil helps form the under surface of tile.

+ Press head helps form the upper surface of tile with the aesthetics.

+ Bead of mold helps form the edge of tile. It is assembled in the body of mold and bear the friction and abration with press head. So that, the durability of bead and press head decides the durability of mold directly.

The structure of cement tile mold

The manufacturing technology of cement tile mold

From the detailed drawing, manufacturing is the next step.

The parts of mold is 3D modeling, programming by CAD-CAM, choose the suitable machine and method for manufacturing.

The input materials are checked and controlled carefully to remove the errors completely.

Manufacturing process on CNC machine ensure the parts having the shape and size as requirements.

Next is the process of heat treatment and surface processing after heat treatment such as flat grinding, polishing, ...

The mold will be assembled and checked the technical specifications before delivery.

Manufacturing is the segment, deciding the durability, shape, dimension and aesthetics directly. Therefore, it needs to process carefully. To ensure the durability of mold, the precision of shape and dimension and the aesthetics of tile, all the parts of mold are processed by CNC, intergrate with heat treatment, spray method and process the surface. Therefore, the mold has the malleable inner layer and the hard outer layer.

The factory for producing cement tile mold DMCLINE

Choose the supplier of cement tile mold

Cement tile mold is working in a hard working environment and bear a high pressing from 100 to 200 tons. The main materials of tile are cement, sand, ect. These materials are easy to abrade metal highly. Therefore, choosing a reputation manufacturing company having capacity is an important step.

The durability of mold depends on the precision of pressing machine and the types of tile. If you use the mold of a domestic supplier, you can save time for maintain, repair as well as save cost.

With the high demand of market, the diversify of mold model is a competitive factor when choosing supplier.

DMC has more than 10 experienced years in manufacturing and transferring technology. We have localized completely the production line to save time, cost and human resource for customer but still ensure the requirement of quality and model of products.

As a fully active company in manufacturing with a quick warranty and maintenance policy. Therefore, detailed instructions on how to use, replace, clean, maintain and produce the mold according to your requirements (color, size, ..), DMC is your perfect choice.