D6 Concrete Block Making Machine

The meaning of name D6.4

- D means the name of concrete block making machine with the brandname DMCLINE;

- 6 means the number of blocks per press time with size 400x200x200;

- 4 means the 4th version using servo pressure - vibration technology;

Technical specifications of D6 - G4 concrete block machine

| Designed capacity | 60 000m3/year (size 400x200x200mm) |

| Cycle time | 15 ÷ 25 s |

| Power | 134.75 Kw |

| Vibration mechanism | Table vibration |

| Pallet | Plastic: 720x880x20mm; Steel: 880x720x10mm |

| Warranty | 12 months |

| Place of origin | DMC Vietnam |

| Workers | 20 workers/2 shifts (include loading & unloading workers) |

| Factory area | 4 984 m2 (include finished products yard) |

The number of workers to operate D6 - G4 block making machine

| Factory manager | 1 worker |

| Worker for operating machine | 4 workers |

| Worker for operating dumper | 2 workers |

| Worker for operating forklift | 4 workers |

| Worker for loading wet block | 8 workers |

| Worker for cleaning up | 1 worker |

Factory area of D6 -G4 block making machine: 4 984 m2

| Workshop | 216 m2 |

| Area for drying wet blocks | 1 026 m2 (for 16 hours) |

| Area for containing finished products | 1 705 m2 |

| Area for input materials | 1 057 m2 |

| Area for office and others | 373 m2 |

| Area for interal yards and trees | 607 m2 |

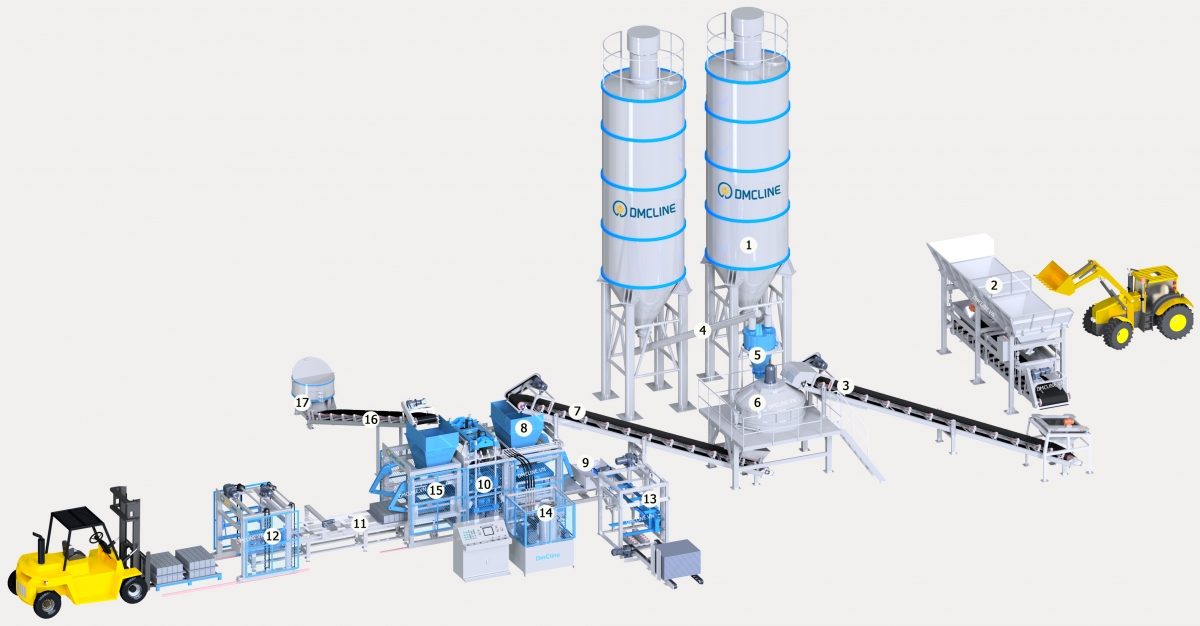

Technology description of D6 - G4 concrete block production

(1) Silo: A Special purpose storage contains cement. Besides the steady steel structure, it includes dust filtering system, anti-clogging aeration and safety valve.

(2) Batching machine: Include two or three materials hoppers. After feeding materials fully into hopper, they will be scaled exactly before transferring into machine

(3) Belt conveyor: Transfer materials after scaling to mixer

(4) Screw conveyor: transfer cement and fly-ash from silo to cement scale

(5) Cement scale: Include a bucket and a scale. Scaled data will be displayed on control center to help workers monitor the production process easily

(6) Mixer: Aggregates (grind stone, sand, thermal slag, ect), water and cement after scaling are mixed together evenly as the setting parameter.

(7) Belt conveyor: Transfer materials after mixing to material dividing machine

(8) Material dividing machine: Store and deliver materials after mixing to block making machine

(9) Pallet feeder: Put pallet into block making machine to bear products and push them to block conveyor

(10) Block making machine: Being designed integratively between pressure, vibration pressure and forced vibration pressure. It creates a strong pressed vibration force to form blocks with high quality and uniformity.

(11) Block conveyor: Clean the surface and transfer block pallet to block stacker

(12) Block stacker: Receive block tray from block conveyor, stack in wooden pallet then the forklift transfers them to dry

(13) Pallet stacker: Receive pallets from forklift or block pulling car; feed into pallet feeder automatically (this machine can be replaced by a pallet feeding worker)

(14) Cooling machine: Cool the hydraulic oil by circulating water pump system

(15) Color feeding machine: Receive the surface material mixture of interlocking block, paver block, ect, then feed color into the mould of block making machine

(16) Belt conveyor: transfer surface material mixture after mixing to color feeding machine

(17) Pigment mixer: mix the materials such as cement, sand, color matter, water, ect together to make a surface materials mixture for interlocking block, paver block, ect.

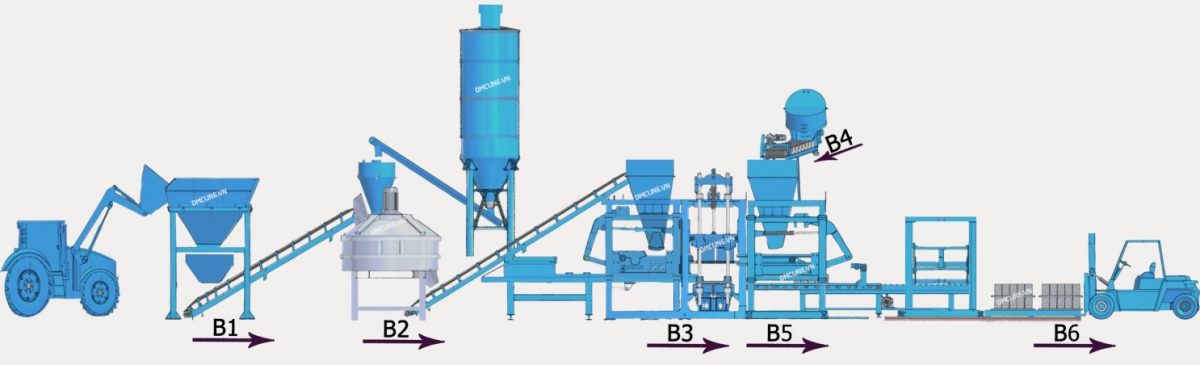

Production process of D6 - G4 concrete block

(B1) Step 1: The dumper feeds materials (stone, sand, ash, slag, ect) into hoppers to scale.

(B2) Step 2: The materials after scaling are mixed together with cement and water.

(B3) Step 3: The pressure - vibration machine forms block piece as the mould. In this process, workers must regularly check to adjust timely to limit the error products.

(B4) Step 4: Mix the materials such as cement, sand, color matter, water, ect together to create the mixture of surface materials for interlocking block, paver block, ect

(B5) Step 5: The materials for surface are discharged to belt conveyor and transfered to pigment feeding machine. Color is fed in the surface of block, then block making machine vibrates and presses the second time

(B6) Step 6: After forming, blocks are lifted to the yard to dry from 18 hours to 24 hours, then stacked and packaged and transferred to curing yard. After 15 to 28 days, they can be exported

Finished block tray

Finished block bale

Wall without bonding mortar

Interlocking paver block

Slope-protect brick

Grass paving block