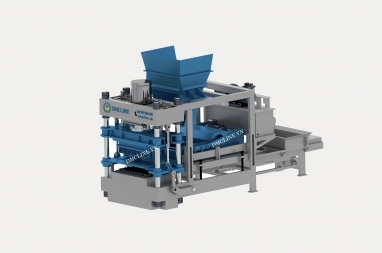

Semi-automatic concrete cover block making machine

Introduction of semi-automatic concrete cover block making machine

Semi-automatic concrete cover block making machine works by the method of double-force static press, the products after pressing and shaping are stacked by workers and brought to the curing yard.

Semi-automatic concrete spacer machine is designed as the Euro standard, using the hydraulic mechanical lever to control the hydraulic xyclinders. Friendly machine design makes it easy for workers to operate, maintain and repair.

By changing the mold, the machine can produce many kinds with different sizes and shapes such as square concrete spacer, H-shaped spacer, four-pointed star spacer, ….

Semi-automatic concrete cover block making machine

Semi-automatic concrete cover block making machine

Technical specifications of semi-automatic machine

| Pressing method | Static press |

| Cycled time | 20-25s |

| Power | 19 kW |

| Spacer tray | Pressed bamboo: 620x400x10mm PVC: 620x400x10mm |

| Warranty time | 12 months |

| Place of origin | DMC, Vietnam |

| Factory area | 300 - 450 m2 (include curing yard) |

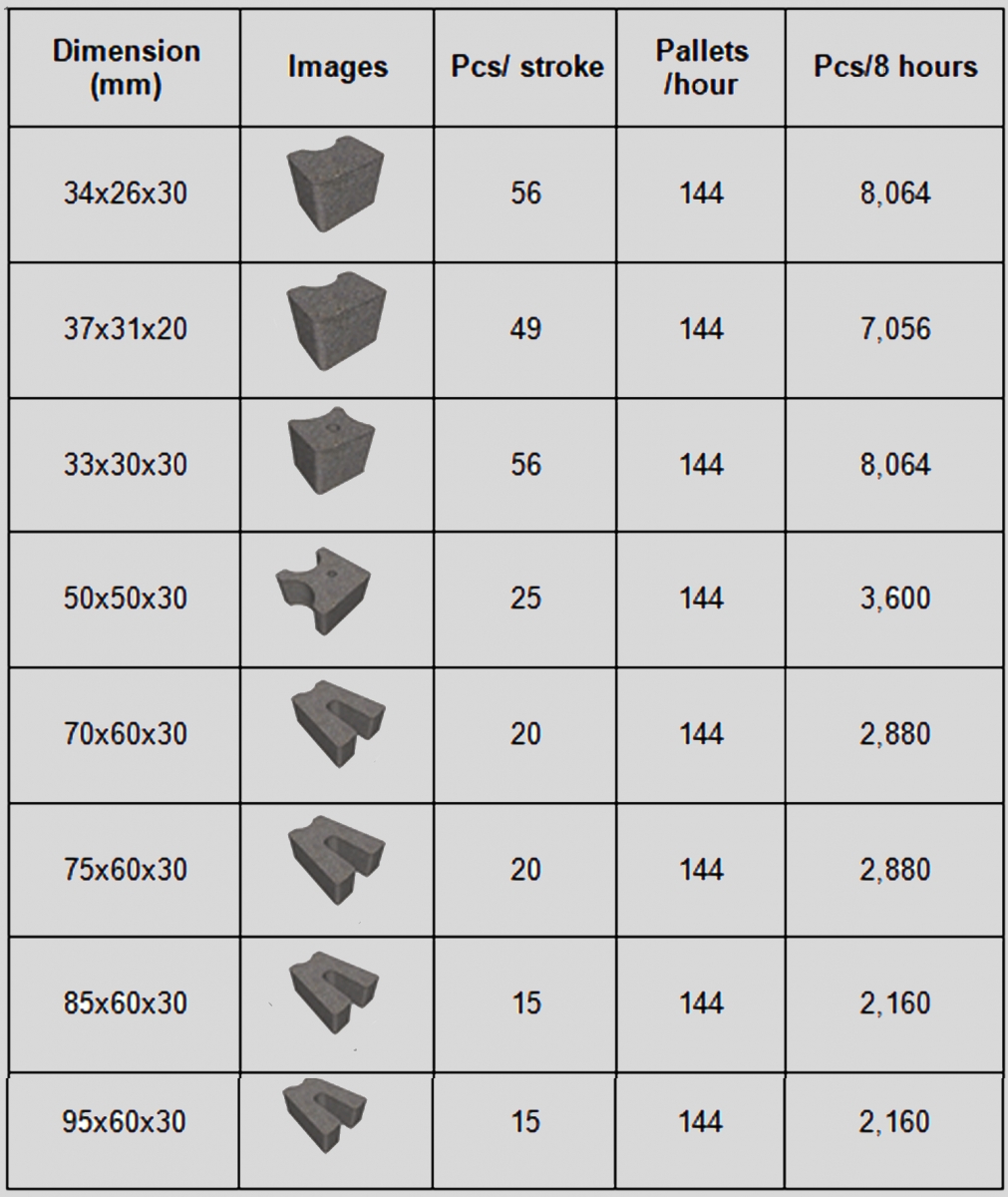

Productivity of semi-automatic concrete spacer machine

Depend on the types, the productivity can be up to 8000 pcs per hour. Below is the table of productivity for your reference:

Productivity table of semi-automatic concrete spacer machine

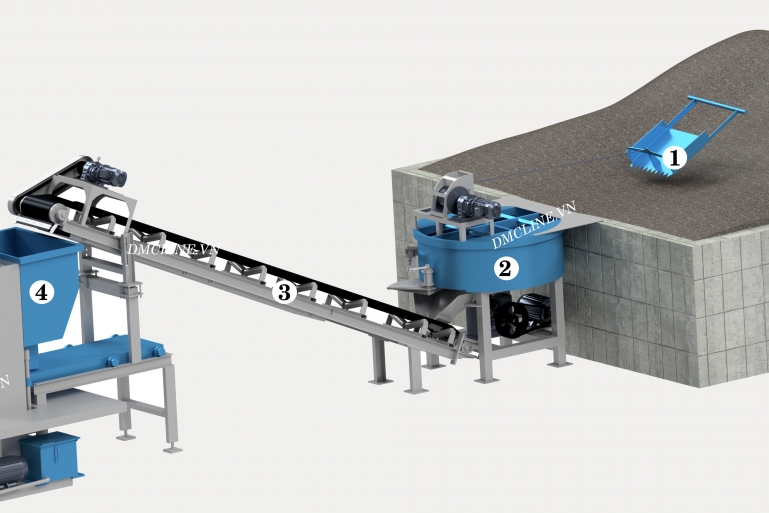

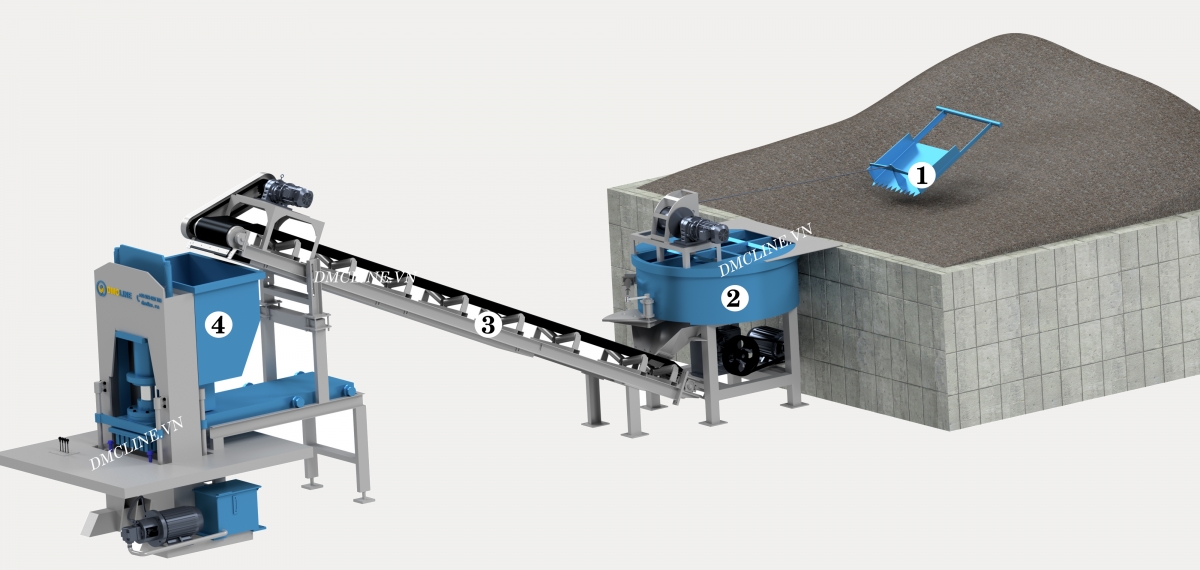

Technology description of semi-automatic concrete spacer machine

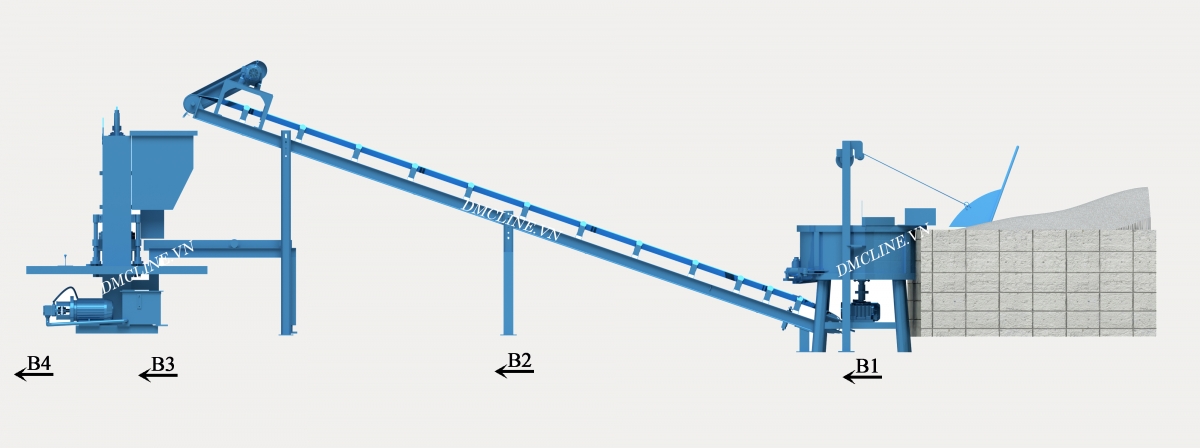

Layout of semi automatic machine

Layout of semi automatic machine

1. Hoist tipping bucket: Transfer materials (crushed stone, sand,…) to the vertical mixer.

2. Vertical mixer: The materials, water and cement are mixed evenly as the setting parameters.

3. Belt conveyor: Transfer the mixture after mixing to concrete spacer machine.

4. Concrete spacer machine: Create a large pressing force to form concrete spacer with high quality and uniformity.

Production process of semi-automatic machine

Production process of semi-automatic machine

Production process of semi-automatic machine

Step 1: Workers feed stone, sand, cement, water to mixer. Then all all ingredients are mixed evenly.

Step 2: Belt conveyor transfers the mixture to concrete spacer machine.

Step 3: Concrete spacer machine forms spacer as the mold. In this process, workers have to check regularly to adjust machine timely to limit the error products.

Step 4: After forming, workers transfer the tray with concrete spacerto the curing yard.

Application of concrete spacer

Concete spacer is an small accessory, but it has a key role in protecting reinforcing cage during the process of filling concrete and impact on the rough construction quality of the house significantly.

Application of concrete spacer

Application of concrete spacer

Therefore, to ensure the quality of construction, concrete spacers are used most popolar in Vietnam and many countries in the world.

If you are interested in this machine, please kindly contact us via Hotline: +84.376.377.123

Related products

The first concrete spacer machine in Vietnam. A low investment cost, the capacity is up to 24.000 pcs/hour. 01 year warranty. Supporting service 24/7.