Automatic concrete cover block making machine

What is an automatic concrete cover block making machine?

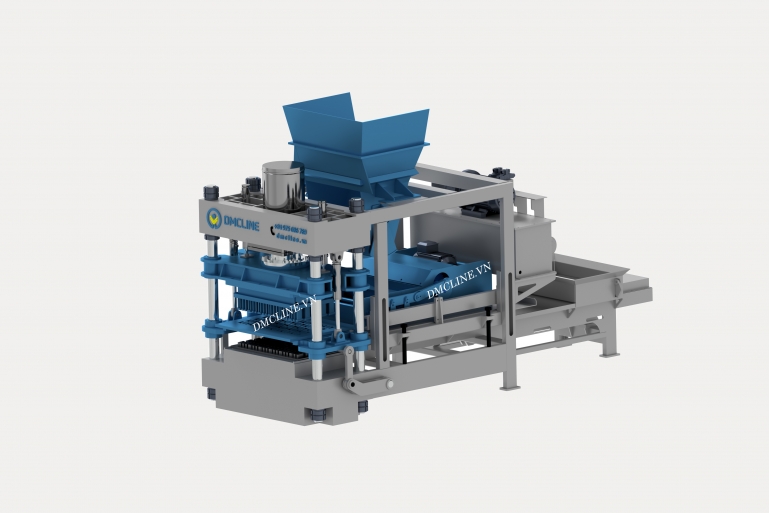

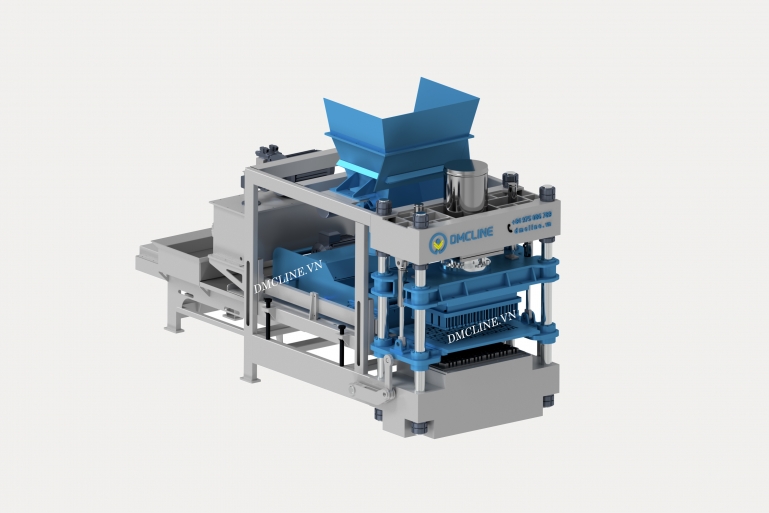

Automatic concrete cover block making machine is also called as concrete spacer machine, cover block machine, concrete cover block machine,… using the static press method to form concrete spacer.

Concrete spacer is an essential thing in the process of filling concrete for beam, collumn, floor to assure the exact concrete layer as the regulation design.

There are some materials of spacer such as concrete, plastic, granite stone, steel. However, using spacer from steel, plastic, granite stone has some disadvantages due to the materials are not same to the concrete floor. Therefore, investors usually choose concrete spacer for their construction.

Application of the automatic concrete cover block making machine help increase productivity and quality of product, save labor cost as well as diversify the shape and dimension of products.

Some types of concrete spacer

Some types of concrete spacer

Technical specification of automatic concrete cover block making machine

| Pressing method | Static press |

| Cycled time | 20-25 giây |

| Power | 32 kW |

| Spacer tray | Pressed bamboo: 880x550x20mm PVC: 880x550x20mm |

| Warranty time | 12 months |

| Place of origin | DMC, Vietnam |

| Factory area | 540 m2 (include curing yard) |

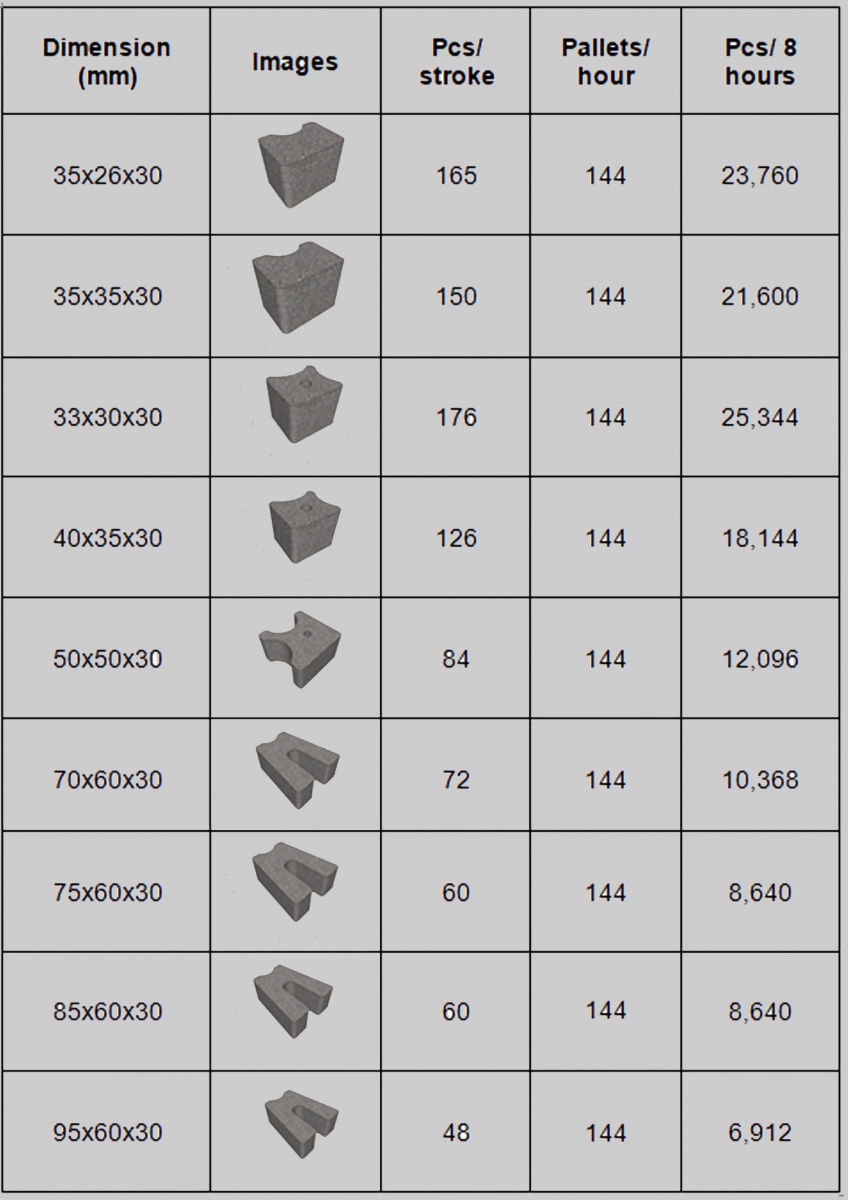

Productivity of automatic concrete cover block making machine

DMCLINE concrete spacer machine can produce many types of concrete spacer with the difference of shapes and dimensions. Below is the productivity of some types:

Productivity table of automatic machine

Besides, DMC can design mold as the requirements of customers.

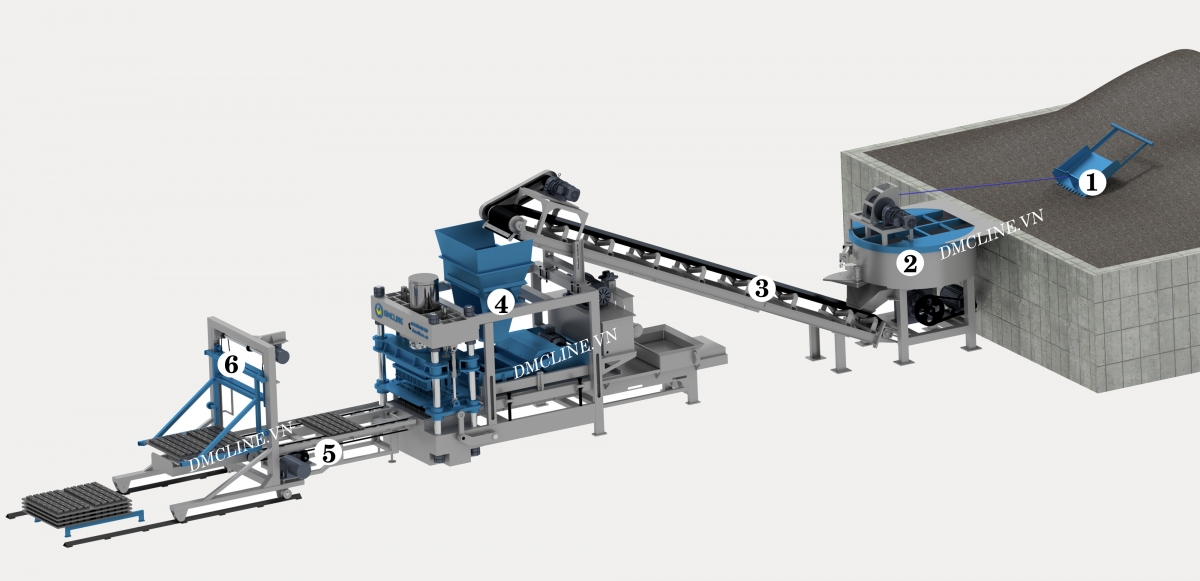

Technology description of automatic concrete cover block making machine

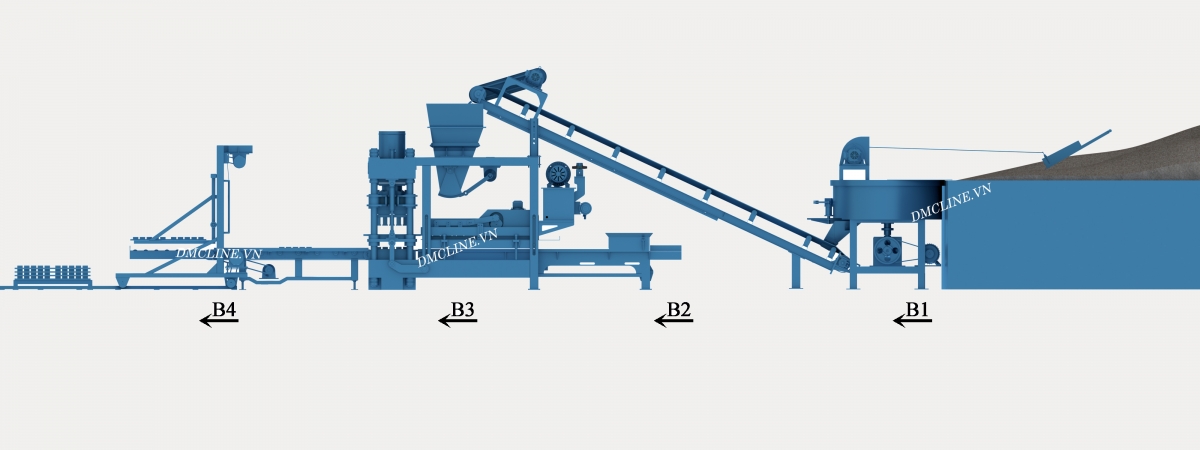

Layout of automatic concrete spacer machine

1. Hoist tipping bucket: Transfer materials (crushed stone, sand,…) to the vertical mixer.

2. Vertical mixer: The materials, water and cement are mixed evenly as the setting parameters

3. Belt conveyor: Transfer the mixture after mixing to concrete spacer machine

4. Concrete spacer machine: Create a large pressing force to form concrete spacer with high quality and uniformity.

5. Finished product conveyor: Transfer the tray with concrete spacer to the position of finished product stacker.

6. Finished product stacker: Receive the tray with concrete spacer from finished product conveyor and stack into bales.

Production process of the automatic concrete spacer machine

Production process of automatic concrete spacer machine

Step 1: Workers feed stone, sand, cement, water to mixer. Then all all ingredients are mixed evenly.

Step 2: Belt conveyor transfers the mixture to concrete spacer machine.

Step 3: Concrete spacer machine forms spacer as the mold. In this process, workers have to check regularly to adjust machine timely to limit the error products

Step 4: After forming, finished product stacker stacks the tray with concrete spacer into bales. Then, worker transfer to the curing yard.

Related products

Semi-automatic concrete spacer machine with the productivity up to 8000 pcs per hour. 03 operating workers. 01 year warranty. The No.1 brand in Vietnam