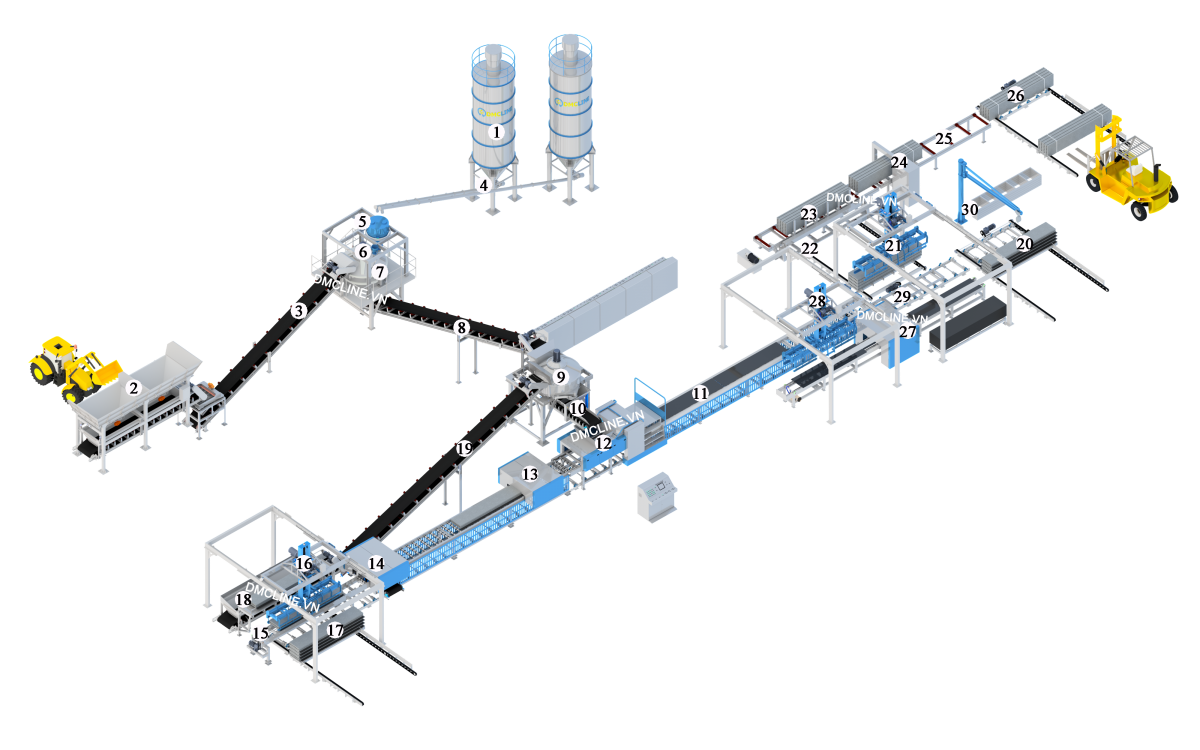

Single lane of automatic wall panel production line

Table of Contents [Ẩn]

Introduction about single lane of automatic wall panel production line

Single lanes of automatic wall panel production line has one lane for extruding materials with the speed from 5 to 6 meters/min. The finished products have a high and stable quality and meet the need of building quickly for construction.

Technical specifications of wall panel production line

| Designed capacity | 500.000m2/year |

| Operaring method | Extrusion |

| Power | 135 kW |

| Forming speed | 5 – 6 meters/min |

| Dimension of wall panel | Width: 600 mm | Thickness: 100/120/150 mm |

| Workers | 3 – 4 people |

| Factory area | 3.500m2 |

| Place of origin | DMC, Vietnam |

Technology description of wall panel production line

1. Silo: A special purposed storage contains cement. Besides the steady steel structure, it includes dust filtering system, anti-clogging aeration and safety valve.

2. Batching machine: Include two or three materials hoppers. After feeding materials fully into hopper, they will be scaled exactly before transferring into machine

3. Belt conveyor: Transfer materials after scaling to mixer

4. Screw conveyor: transfer cement and fly-ash from silo to cement scale

5. Fly ash and cement scale: Include a bucket and a scale. Scaled data will be displayed on control center to help workers monitor the production process easily

6. Addition and water scale: Include a bucket and a scale. Scaled data will be displayed on control center to help workers monitor the production process easily

7. The primary planetary mixer: Aggregates (grind stone, sand, fly ash, etc.), water and cement after scaling are mixed together evenly as the setting parameter at the primary planetary mixer.

8. Belt conveyor: Transfer material after mixing to the secondary planetary mixer.

9. The secondary planetary mixer: Mix the mixture after mixing at the primary planetary mixer with the recycle material, which transferred from the material gathering machine.

10. Material dividing machine: Store and deliver materials after mixing to block making machine

11. Steel plate feeder: Put plates into wall panel making machine to bear products and push them to wall panel conveyor.

12. Wall panel making machine: Create a strong extrusion force to form wall panel with high quality and uniformity.

13. The primary cutting machine: Cut the wall panel after extruding from forming machine as the length of steel plate.

14. The secondary mixer: Re-cut the wall panel to have a flat edge and a size as requirements.

15. Wall panel conveyor: Transfer the plate with wall panel to wall panel stacker.

16. Wall panel stacker: Pick the plate with wall panel, which meets the requirements, and stack in wall panel tray. At the same time, pick the plate with error wall panel to material gathering machine to recycle.

17. Wall panel tray conveyor: Transfer the trays with panel and forklift transfer them to the curing yard.

18. Material gathering machine: Separate the error wall panel from steal plate and recycle

19. Belt conveyor: Transfer the recycled materials to the secondary planetary mixer

20. Panel tray receiver: Receive the tray of wall panels from forklift, and then chain system transfers them to wall panel cuber.

21. Wall panel cuber: Separate wall panel from plate and stack into bales at the position of wall panel conveyor. At the same time, pick steel plate to the position of plate cleaning machine.

22. Panel bale conveyor: Transfer panel bales to the position of baled turning machine

23. Baled turning machine: Turnover the bale of wall panel vertically

24. Bundle-tying machine: Pack the belt for the bale of wall panel.

25. Vertical bale conveyor: Transfer the bale of wall panel vertically to the position of horizontal bale conveyor.

26. Horizontal bale conveyor: Transfer the bale of wall panel horizontally and the forklift transfer to the finished product yard.

27. Oiling and cleaning machine: Clean and oil the steel plates

28. Steel plate stacker: Pick the clean steel plates and stack into the position of steel plate feeder

29. Steel plate and panel tray conveyor: Transfer steel plate and panel tray for the next production cycles

30. Panel tray feeder: transfer panel tray to the position of the steel plate and panel tray conveyor

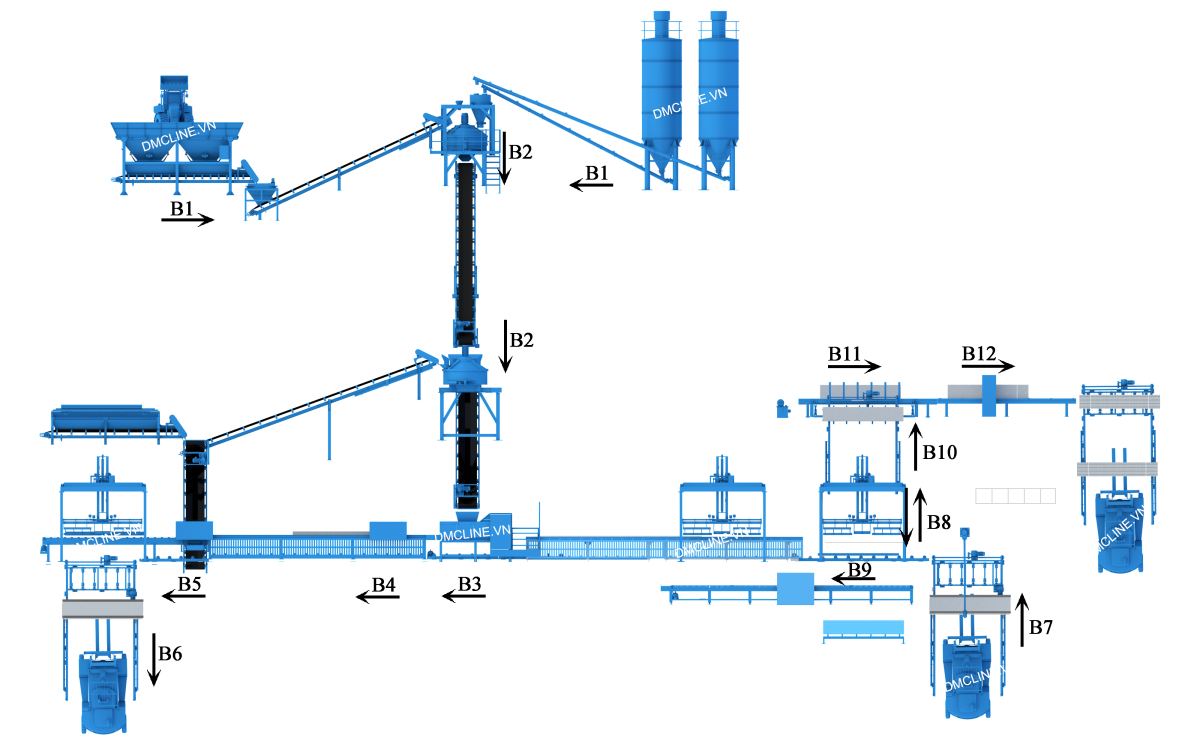

Production process of automatic wall panel production line

Step 1: The dumper feeds materials (dust stone, sand, slag, etc.) to the hopper to measure. Silo feeds cement, fly ash to the fly ash and cement scale. The pump feeds water and additive agent to the additive and water equipment.

Step 2: The materials after measuring will be mixed evenly with cement and water at the primary planetary mixer and discharged to belt conveyor. Then belt conveyor transfers them to the secondary planetary mixer to mix one more time and discharge to the material dividing machine.

Step 3: Wall panel making machine forms panel as the mold. The products, which do not meet the requirements, will be removed to the secondary planetary mixer to mix once more time

Step 4: After extruding from wall panel making machine, the primary cutting machine cuts wall panel as the length of steel plate.

Step 5: After cutting the first time, wall panel will be cut the second time to reach the size as requirements. Residual material after cutting is discharged to the belt conveyor and transfer to the secondary mixer to mix again

Step 6: After forming, wall panel will be transferred to curing yard from 18 to 24 hours.

Step 7: Panel tray receiver receives the tray of wall panels from forklift, and then chain system transfers them to wall panel cuber.

Step 8: Wall panel cuber separate wall panel from plate and stack into bales at the position of wall panel conveyor. At the same time, pick steel plate to the position of plate cleaning machine and produce the next cycle production.

Step 9: Steel plates will be cleaned and oiled. Then the steel plate stacker stacks them into steel plate feeder

Step 10: Panel bale conveyor transfers panel bales to the position of baled turning machine

Step 11: Baled turning machine Turnover the bale of wall panel vertically

Step 12: Pack and transfer wall panel to the curing yard. After 15 to 28 days, it can be sold.