Terrazzo tile machine T2-200

The meaning of name T2-200

- T is the code of terrazzo tile making machine with the brand name DMCLINE;

- 2 is the quantity of pressing machine;

- 200 is the pressing force of 200 tons

Technical specifications of terrazzo tile machine T2 - 200

Dimension of machine | 1880x1320x2312mm |

Power | 15 kW |

Pressing force | 150-180 tons |

Oil tank capacity | 200 liters |

Cycle time | 21-22s |

Operating method | Semi - automatic |

Productivity of size 300x300mm | 160 m2/8 hours |

Productivity of size 400x400mm | 210 m2/8 hours |

Productivity of size 500x500mm | 150 m2/8 hours |

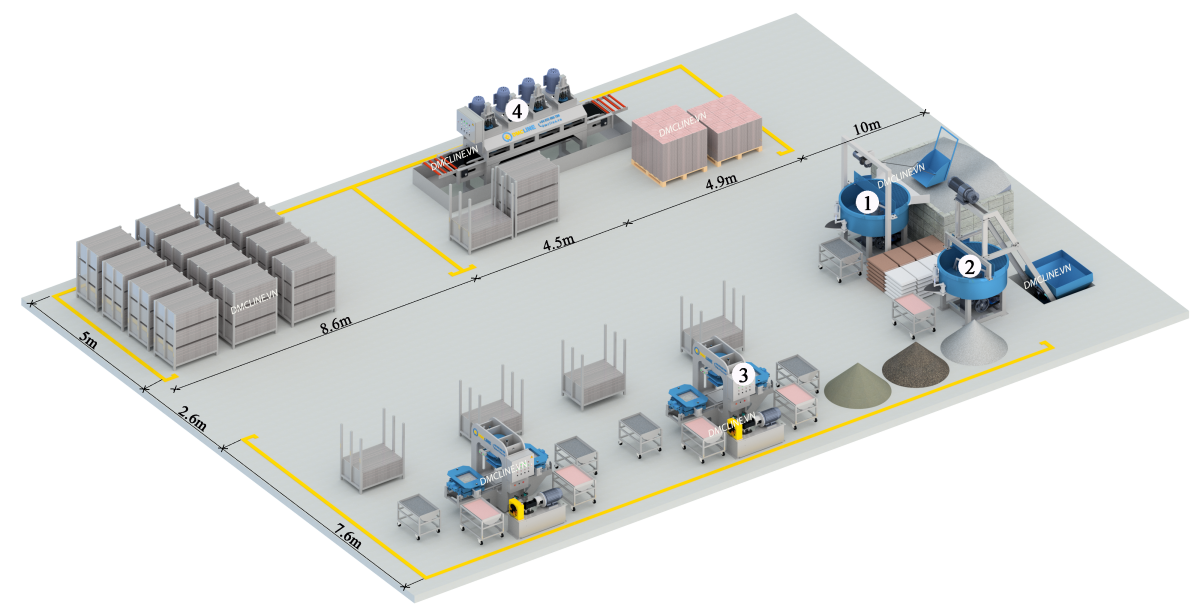

Technology description for producing terrazzo tiles T2-200

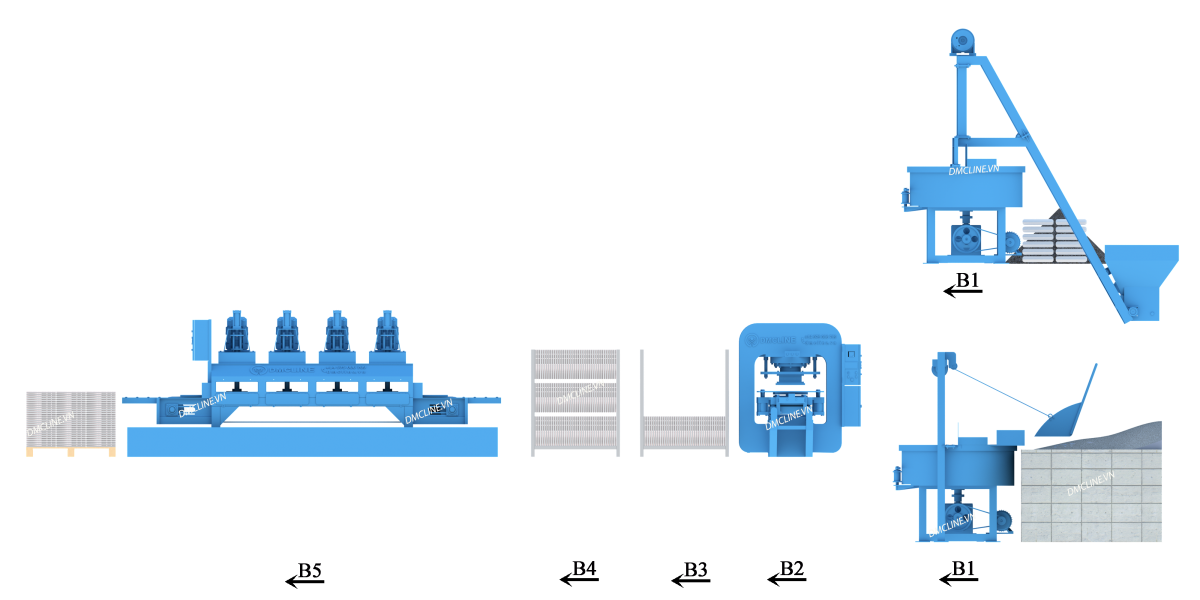

1. Surfaced layer material mixer: Mix aggregates together (include stone powder, cement, sand, pigment, marble) with water evenly to have a semi-liquid mixture.

2. Under layer material mixer: Mix aggregates together (include cement, sand) with water evenly to have a under layer mixture.

3. Forming machine: Form some types of terrazzo tile with shape and size as the mold

4. Tile grinding machine: include the functions as pre-grinding, regrinding and polishing to the surface of tile

Production process for producing terrazzo tile T2-200

Step 1: Mix materials

- Surface layer materials (include marble, cement, stone powder, pigment, water, etc.) are fed to the surfaced layer material mixer. After mixing evenly, the mixture is charged into mortar lorry and transferred to the forming machine

- Under layer materials (include dust stone, cement and water) are scaled in skip hoist and transferred to mixer. After mixing evenly, the mixture charge into mortar lorry and transferred to the forming machine.

Step 2: Form the shape of terrazzo tile

- The mixture of surface layer and under layer is fed into the mold according to the order of the surface layer and the under layer to form two separate layers.

- The forming machine uses a large hydraulic press force to form the shape of tiles in the mold and solidify them.

Step 3: Separate and stack terrazzo tile on the rack

- After forming, terrazzo tiles are separated from the mold automatically by the machine, and then workers stack on the rack. After that, the forklift transfers to the curing position

Step 4: Curing terrazzo tile

- Based on the atmosphere and features of product, terrazzo tiles are cured naturally in 72 hours or cured in steam room in 24 hours before grinding and polishing.

Step 5: Grinding and polishing

- After curing, terrazzo tiles are transferred to the grinding machine to grind and polish the surface layer to have a high aesthetics

- After grinding and polishing, the workers stack into the bales, packaging and transferred to curing yard. After 15 days, it can be sold.