DMCLINE Concrete block stacker

What is DMCLINE concrete block stacker?

DMCLINE Concrete block staker (also called as block Picker or cuber or block separating and gathering system) has been localized and transferred by Doan Minh Cong Joint Stock Company (DMC) since 2017. The product is certified as a scientific and technological product.

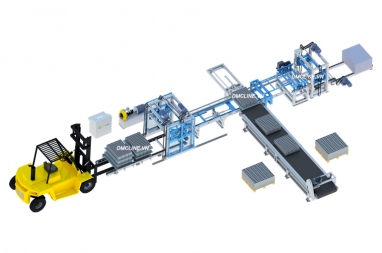

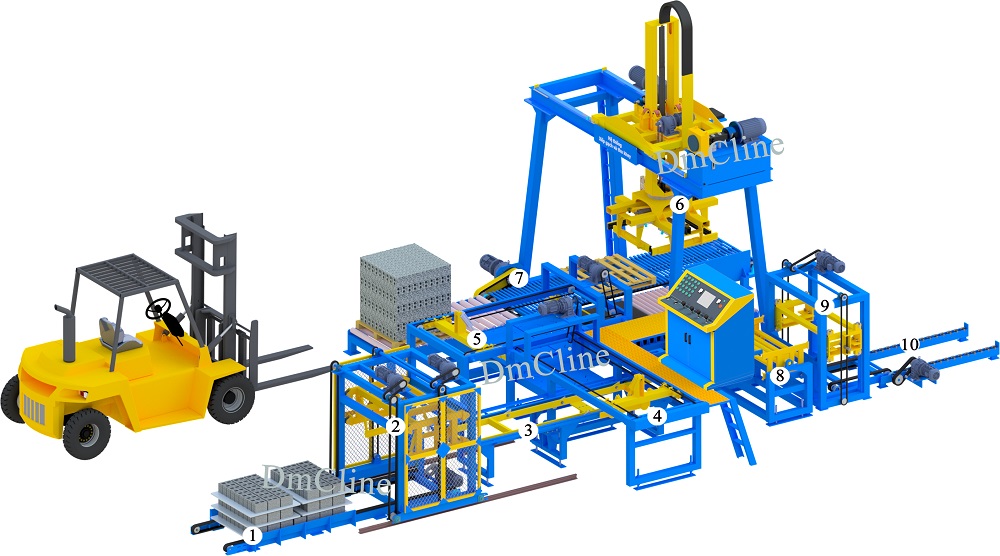

DMCLINE Concrete Block Stacker has been designed automatically from separating block, gathering block, gathering, tumbling and stacking pallet, then stacking block.

Reducing 70% of labor cost, this machine can stack over 30 block types (inlcuding building block and paver block), using for the machine with the capacity of over 10 million standard pieces.

Block stacking and pallet gathering process

(1) Block tray reciever: Receive block tray from forklift, movement rails system push block tray in turn to block tray unloader.

(2) Block tray unloader: Unload block tray in turn to block tray pushing.

(3) Block tray pushing: Push tray with block to horizontal block conveyor and push the tray without block to pallet tumbler at once.

(4) Horizontal block conveyor: Separate and transfer block from block tray pushing to block conveyor and turned machine.

(5) Block conveyor and turned machine: For the horizontal hollow block, it gathers and turnovers the block down and moves to loading conveyor position.

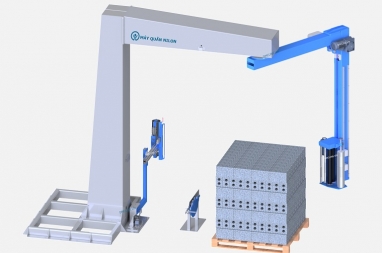

(6) Cuber: Pick the block up from the pending position of loading to the stacked position.

(7) Chain type conveyor: after stacking, the roller transfer the stacked block to the forklift then trasfer to the curing yard.

(8) Pallet tumbler: turnover and clean the pallet.

(9) Pallet gathering machine: Gather the pallet from the pallet tumbler, then stack them.

(10) Pallet bale loader: transfer the pallet bale to forklift.

Technical specifications of concrete block stacker

Capacity | For solid block: 165 pallets/hour For vertical hollow block: 140 pallets/hour For horizontal hollow block: 100 pallets/hour |

Pallet size | Designed according to the customer |

Block Bale Size | From 0,78m to 1,2m |

Block Type | Over 30 block types (build block and paver block) |

Power | 45 Kw |

Warranty | 12 months |

Place of origin | DmC Vietnam |

Workers | 03 |

Workshop | 250 m2 |

Why should you choose DMC Concrete Block Stacker?

Firstly, DMCLINE Concrete Block Stacker can stack over 30 different block types as solid block, hollow block, decorating block, paver block…

Secondly, The machine can stack block bales with size from 0,78m to 1,2m.

Thirdly, Price of block separation machine from 700,000,000 to 1,500,000,000 VND (only equal to 40% of imported machine).

Fourthly, Committing to repair and warrant quickly (presence within 24 hours upon request).

DMC commits to pioneering the creation and improvement of the best and most useful solutions to promote the durable development of concrete block production community.

DmC is proud to be the first company manufacturing block stacker successfully in Vietnam.

The price of Block Separation Machine

Depending on the capacity selected by investor, the price of block staker is from 700,000,000 to 1.500,000,000 VND. Because Vietnam has mastered the technology, this is a very low price, only 20-50% compared to Korean block stacker, Japanese block stacker, Spanish block block stacker...

Video was filmed at the factory of DMCLINE's Customer

Related products

Contact 0975085689 to buy DMCLINE Concrete Block Separation Machine, Separation Machine reduce 40% of labor cost, 100% automation, low price, easy operation, stable operation, 1500 pallet/shift capacity, One (1) year warranty. Scientific and technological product

Save over 30% of nylon when using DMCLINE nylon wrapping machine. This machine is made in domestic so it has a low price