Production process of terrazzo tile

Terrazzo tile is one of the most popular unburnt brick, use for paving sidewalk, garden yard, school yard, etc. Therefore, how can we produce terrazzo tiles?

Table of Contents [Ẩn]

Introduction about terrazzo tile

Terrazzo tile is also called as interlocking paving block. The main materials are cement, sand, crushed stone, powder stone, color powder, granite stone. Terrazzo is produced by hydraulic pressing method. Two separated motar components (surface layrer material and under layer material) are pressed together and have a high strength.

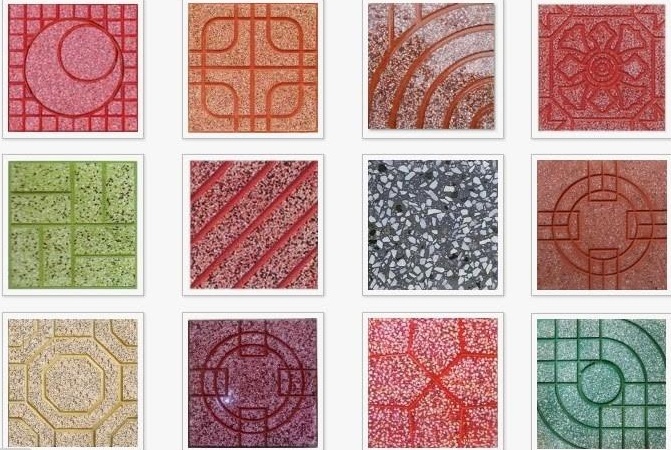

Some popular terrazzo tiles

The difference of tiles is mainly about the shape, size, thickness as well as the components of surface layer. They are also the factor, which decide the complete surface of this layer. Afer pressing, terrazzo tile will be grinded, polished and chamfered

Terrazzo tiles use for paving sidewalk

Production process of terrazzo tile with DMCLINE terrazzo tile making machine

At the present, DMC has launched T2-200 model to the market. This machine is controlled by PLC and advanced sensor system with hydraulic system according to Euro standard. The lastest technology helps the machine to operate with high productivity and stability, the finished products meet the standard of quality and aesthetics.

Production process of terrazzo tiles

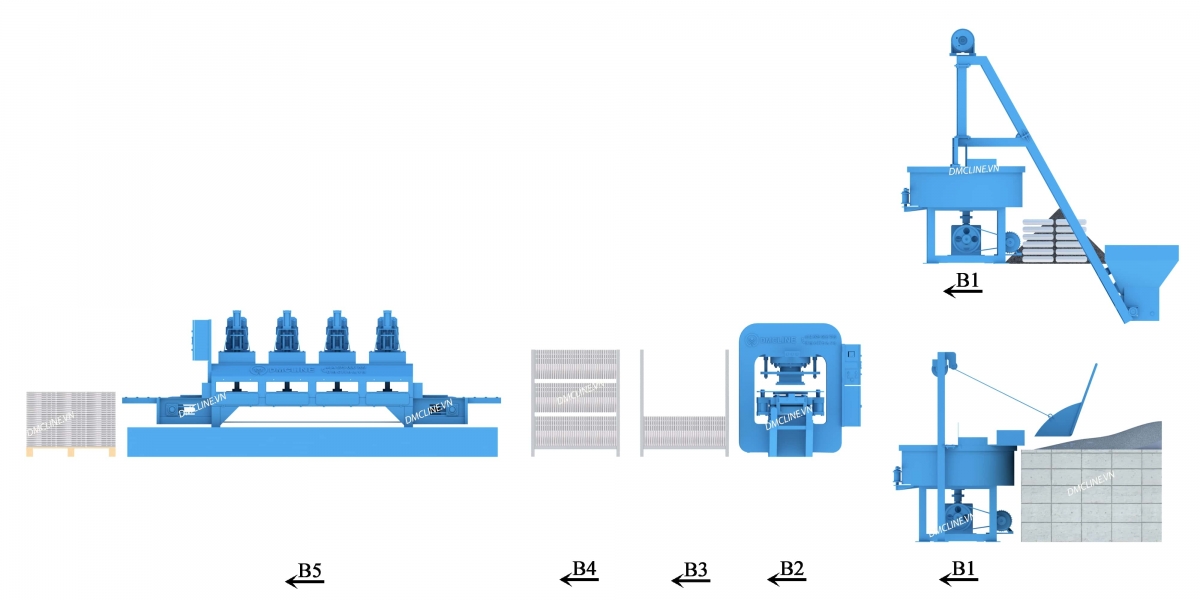

The production process of terrazzo tile as below:

1. Mix materials

Terrazzo tiles have two layers: under layer and surface layer. The materials of under layer include crushed stone, cement and water. The worker scales materials and feeds to skip hoist, then transfers to the mixer.

The material mixture after mixing evenly will be discharged into mortar lorry and transferred to the forming machine

The materials of surface layer, include: marble, sand, powder stone, cement, pigment, water, ect, are fed to the mixer. After mixing evenly, the mixture is discharged into mortar lorry and transferred to the forming machine

2. Transfer materials to the mold

The mixture of surface layer and under layer is fed into the mold according to the order of the surface layer and the under layer to form into two separate layers

3. Form the shape of terrazzo tile

The forming machine uses a large hydraulic press force to form the tiles in the mold and solidify them.

After forming, terrazzo tiles are separated from the mold automatically by the machine, and then workers stack on the rack.

4. Curing terrazzo tile

Based on the atmosphere and features of product, terrazzo tiles are cured naturally in 72 hours or cured in steam room in 24 hours before grinding and polishing.

5. Grinding and polishing

After curing, terrazzo tiles are transferred to the grinding machine to grind and polish the surface layer to have a high aesthetics

After grinding and polishing, the workers stack into the bales, packaging and transferred to curing yard. After 15 days, it can be sold.

More than 14 experienced years in manufacturing and transferring the production line of non-fired building materials and some types of mold such as concrete block mold, terrazzo tile, cement tile, ect, DMCLINE is confident to be the most perfect supplier for your choice!